Moving Forward Instead of Standing Still

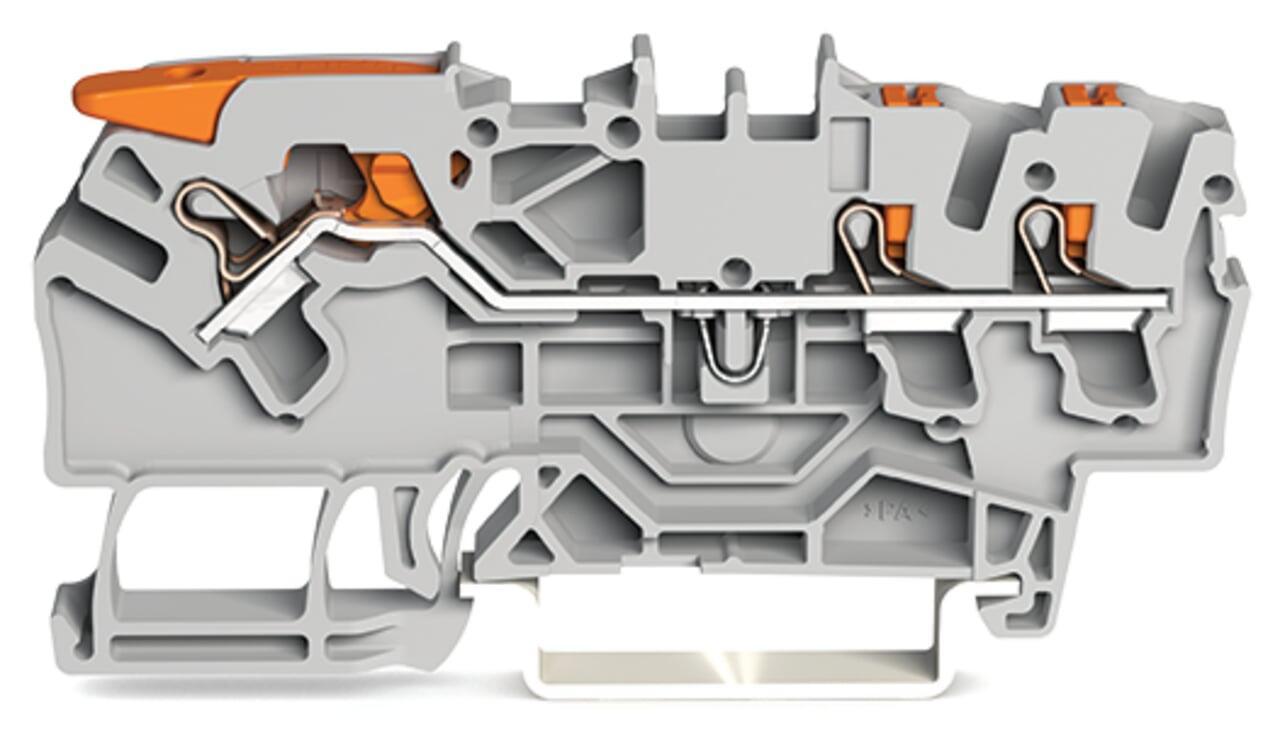

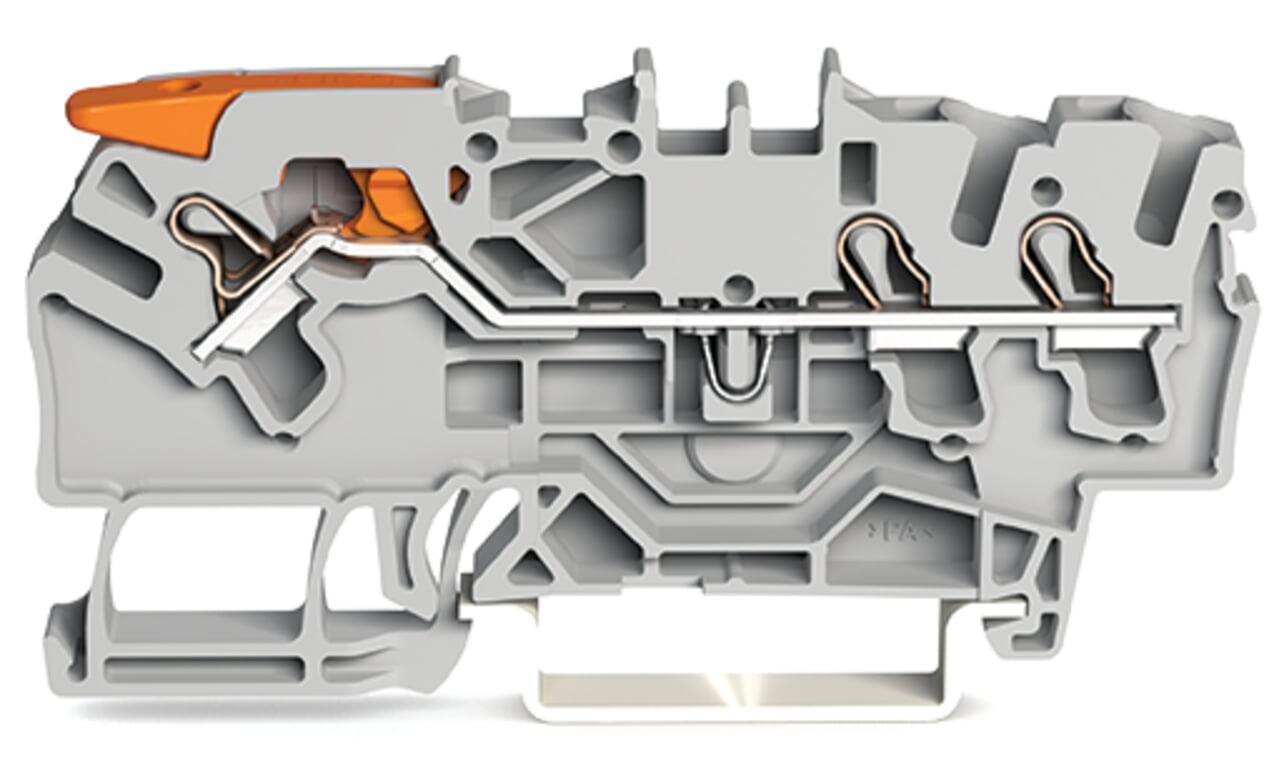

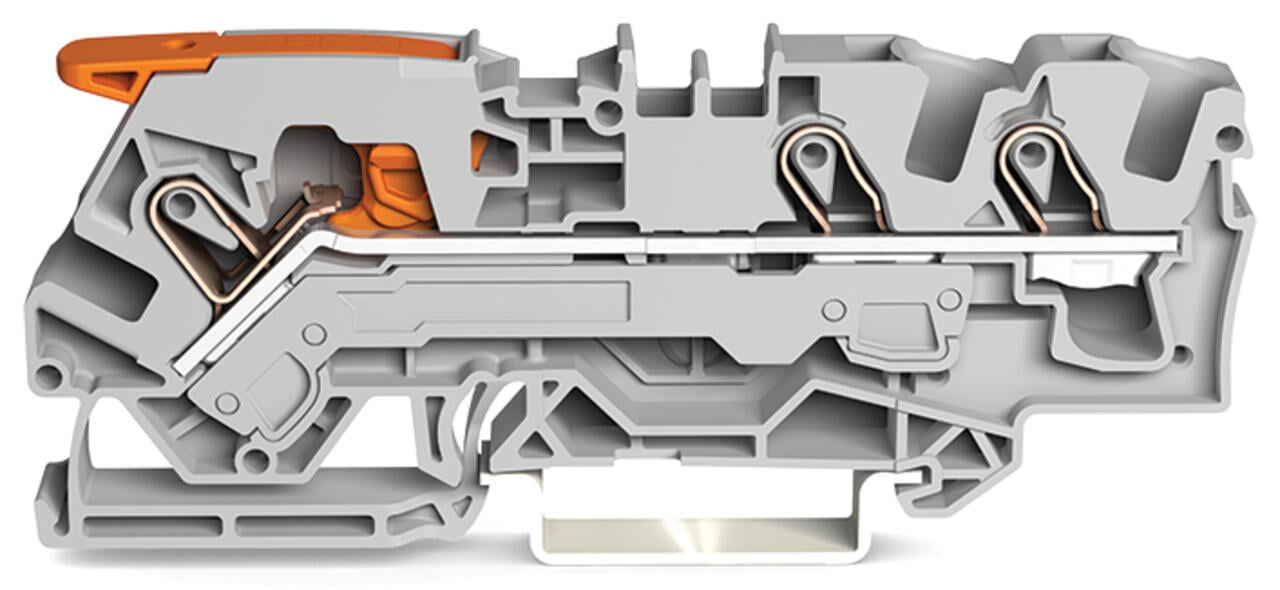

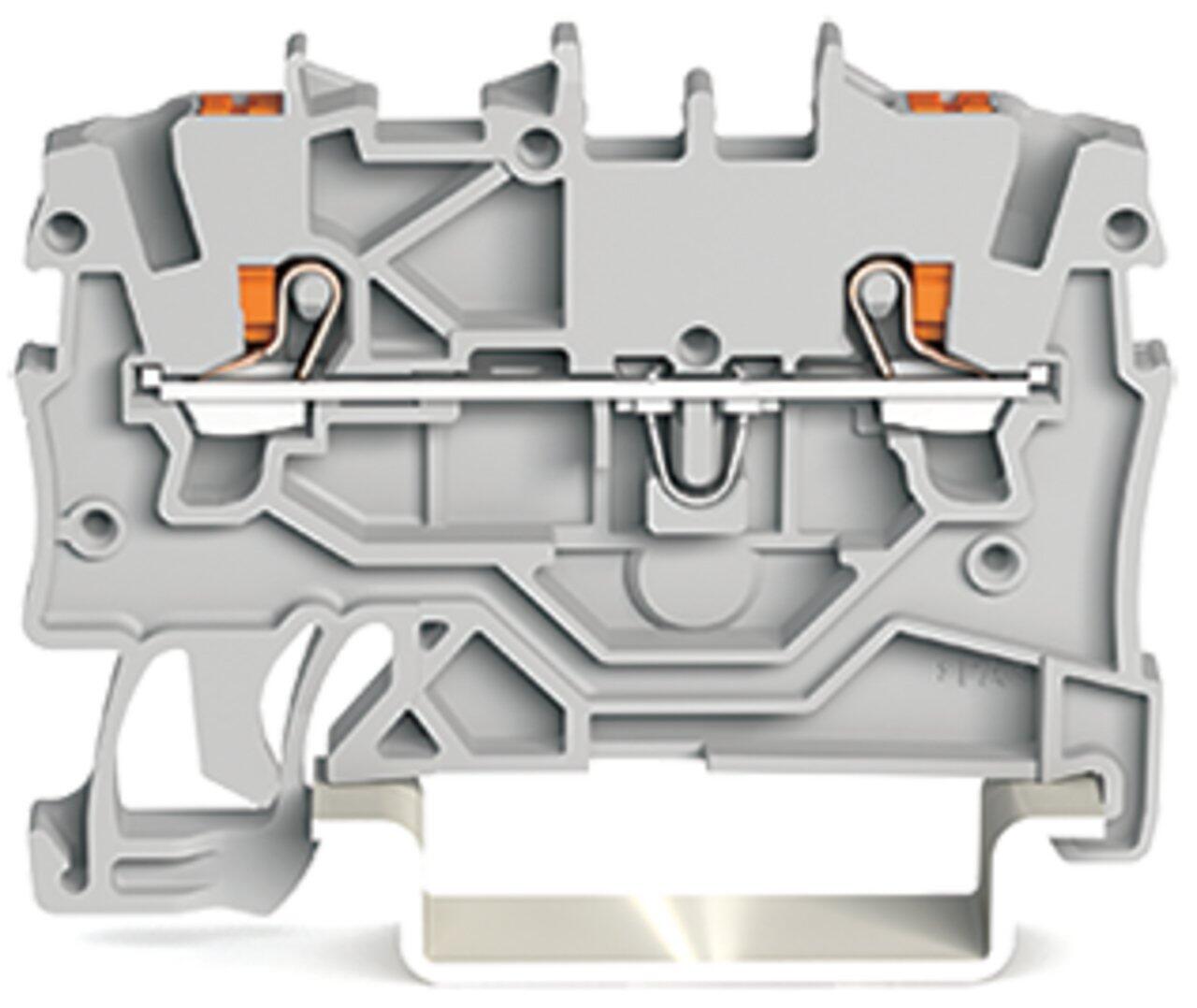

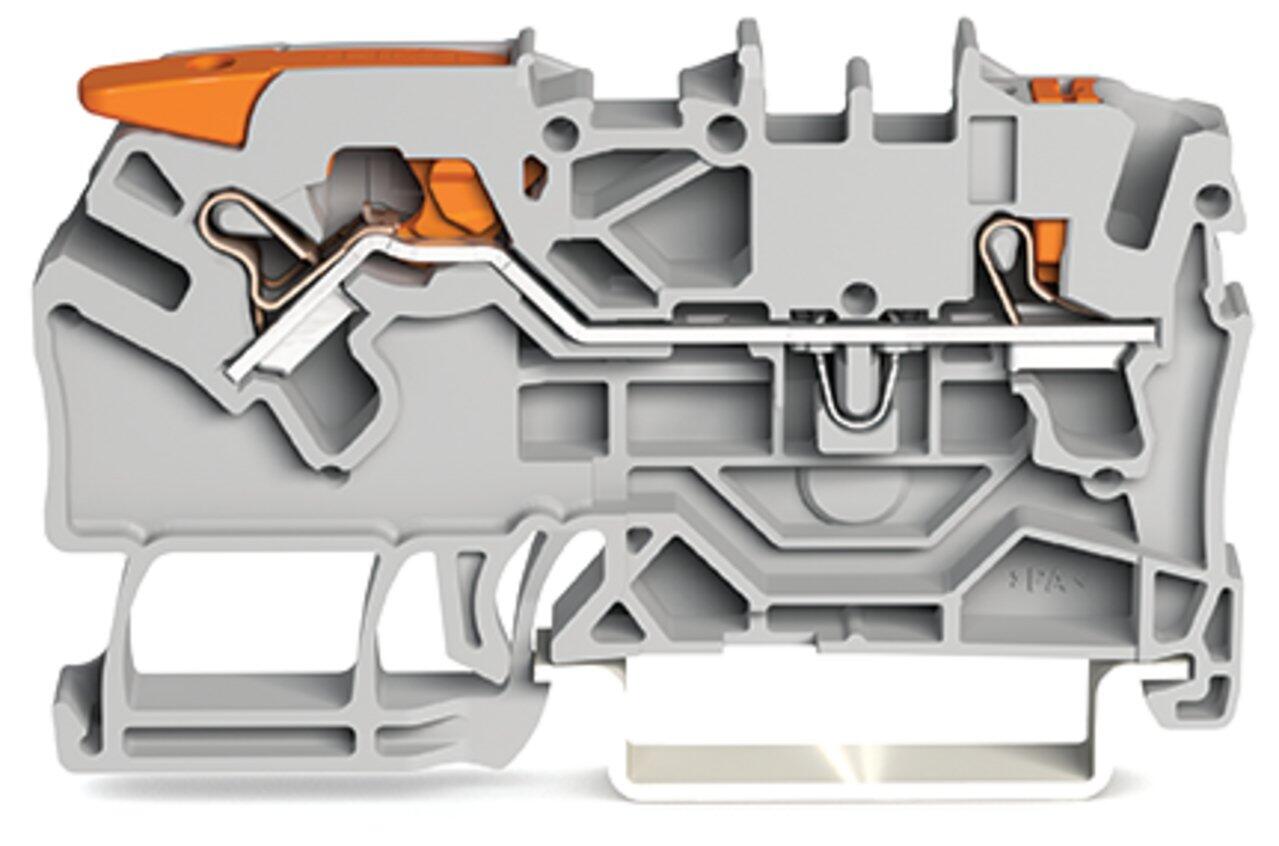

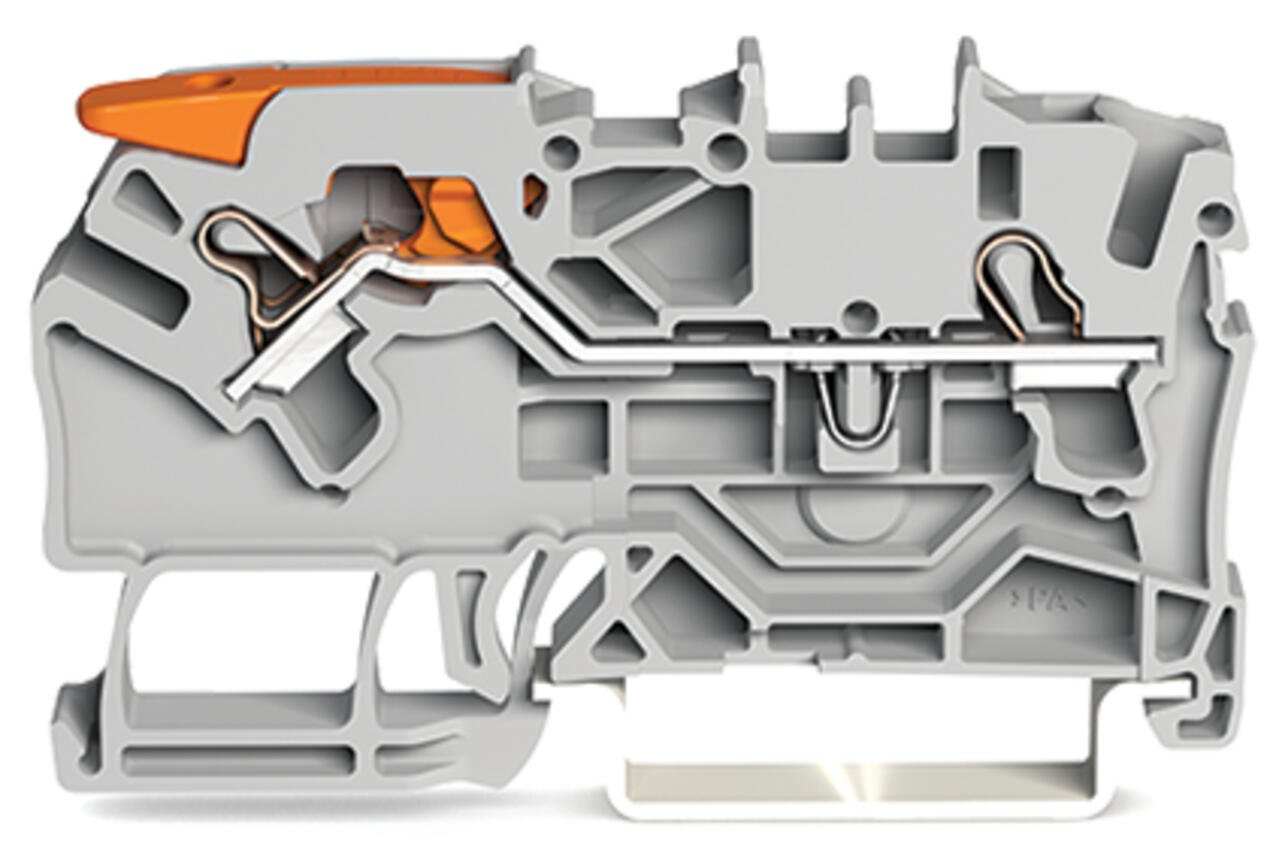

Conveying, emptying, filling, dosing – HECHT has been testing the behavior of bulk goods in its technical center for several years. Short reaction times are also important here for attaching and detaching sensors or for product changeovers. This work is made much easier by using the new WAGO TOPJOB® S Rail-Mount Terminal Blocks with levers. Sebastian Wiesenbart, director of Automation Technology at HECHT, tells us the whole story of their success.