Implement Safety Applications Without a Safety Controller

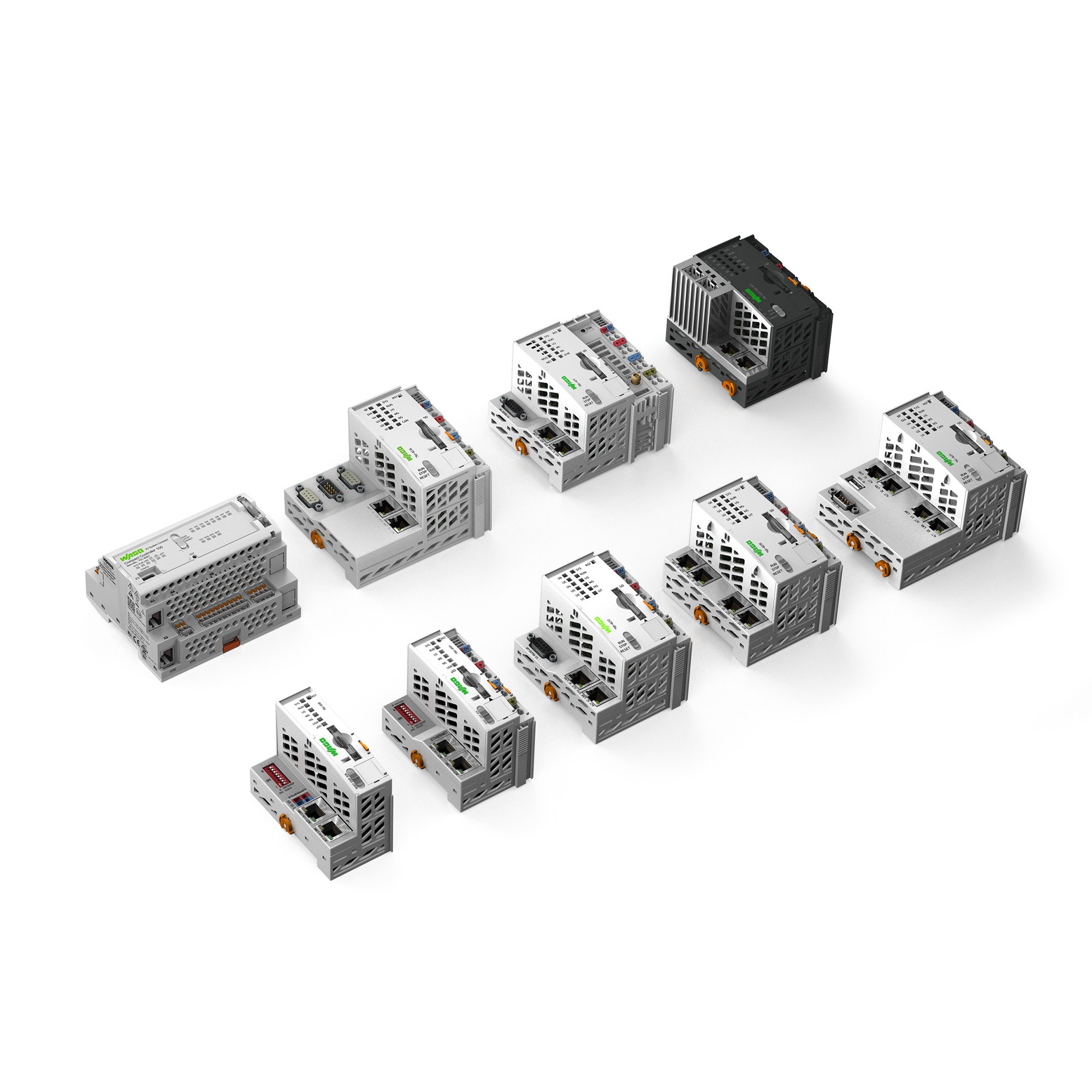

New safety modules can be operated with WAGO controllers.

WAGO’s new safety modules now enable users to implement safety applications, such as two-hand operation or door locking, without the need for a separate safety controller. The logic modules can be used downstream of WAGO controllers and couplers, resulting in faster reaction times at the lowest field level because communication via the fieldbus is eliminated.

The safety logic is configured using the new Safety Editor. Thanks to the logic modules, a machine can now be implemented with WAGO controllers, such as the PFC, including a safety application.

Another advantage: The module can also be integrated behind a safety controller via PROFIsafe. This enables faster safety response times and allows for the creation of more compact safety applications.

Your Benefits:

- Cost-effective solution for safety applications

- Can be used without a safety controller

- Faster safety response time, since the logic is executed directly in the module

Item Numbers:

- 750-667/000-104

- 753-667/000-104

- 750-666/000-104

Larger Process Image, More Flexible Application Options

The New 4-Port IO-Link Master

The new 4-Port IO-Link Master (item no. 750-1657) for the WAGO I/O System 750 supports simultaneous operation of up to four different IO-Link devices or standard digital sensors/actuators, regardless of the fieldbus. The module offers increased performance and other innovations, such as a larger process image, thus meeting the requirements of IO-Link test specification V1.1.3 of January 2021.

For example, up to 32 bytes of process data can now be transmitted for one port in each transmission direction without the need for a control program to defragment/fragment the process data. This makes the 4-Port IO-Link Master more flexible for WAGO IO-Link devices.

Together with the WAGO IO-Link Configurator, it is also easy to configure and parameterize the IO-Link devices.

The Benefits for You:

- Higher performance thanks to more powerful hardware

- Data transmission up to 32 bytes per port/128 bytes per module

- Overload protection of the sensor supplies

Item Number: 750-1657

Greater Performance, Precision and Speed

The New WAGO Proportional Valve Module

A new module (item no. 750-1632) joins WAGO’s line of proportional valve modules. With a 2-, 3- and 4-wire control system, it enables users to conveniently control the hydraulics and pneumatics of their systems with one single module. In addition, adaptive valve adjustment ensures automatic detection of the electrical valve properties and corresponding adjustment of the control parameters.

The new module boasts greater precision, shorter response times and more in-depth diagnostics and is intended to replace the earlier proportional valve module (item no. 750-632/000-100) in the long term. It allows users to implement even more demanding applications – and to control movements of the hydraulic axis even more precisely, for example. In addition, the probability of error between the setpoints and actual values is reduced. Another advantage: The module is integrated directly in the I/O node and no separate module from a specialty vendor is required, making it a cost-effective option.

Your Benefits:

- Higher precision

- Faster response time

- Better diagnostics

Item number: 750-1632/000-100

Same Width, More Channels

A new module for pulse width modulation (PWM) offers greater flexibility and allows more applications.

The new 4-channel pulse width modulation module for the WAGO I/O System 750 is only 12 mm wide, but can control up to four channels and switch between five operating modes. That opens up more possible applications – especially for instrument and control engineering users – saves space and reduces costs. The module also offers a current carrying capacity of 0.2 A per channel, which can be increased to 0.4 A through parallel connection, and a switching frequency up to 20 kHz. Flexible switching between operating modes is possible, for instance between a variable duty cycle and variable frequency. That way, the same module can be used for different kinds of PWM control. For example, in heating control, the new PWM module allows precise readjustment instead of just two-point control. As an XTR version for extreme environments (Item No. 750-677/040-000), the module can also meet more challenging requirements, such as extreme temperature resistance, increased dielectric strength and high vibration and shock resistance.

Your Benefits:

- Four channels in a width of only 12 mm (0.472 inch)

- Current carrying capacity up to 0.2 A per channel; switching frequency up to 20 kHz

- Adjustable operating modes for a wide variety of applications

Item Numbers: 750-677 and 750-677/040-000 (XTR version)

Easy Integration of EnOcean® Sensors and Actuators

New RS-485 Gateway from WAGO

The EnOcean® wireless sensor protocol has established itself as the standard in the building industry, above all because it allows use of battery-free sensors and control elements – for example, in room automation, lighting systems and many other applications. The energy for wireless transmission is usually generated via energy harvesting. WAGO is now launching an EnOcean® gateway that can be connected easily to the WAGO I/O System 750 via a serial interface, with either a serial module of the WAGO I/O System or a controller with an integrated serial interface. The use of standard protocols like Modbus® and ESP-3 simplifies bidirectional communication between the I/O System and the EnOcean® modules. Serial transfer also allows long cable lengths so that the gateway can be installed far from the I/O System. This convenience is especially important when the engineering room that houses the controller and I/O System is located at a distance. The intelligent design also permits mounting in a visible location, such as on a wall or ceiling.

Your Benefits:

- Easy EnOcean® connection to the WAGO I/O System 750

- Attractive design for visible wall or ceiling mounting

- Installation possible at a significant distance from the WAGO I/O System

Item Number: 750-940

Available: in stock