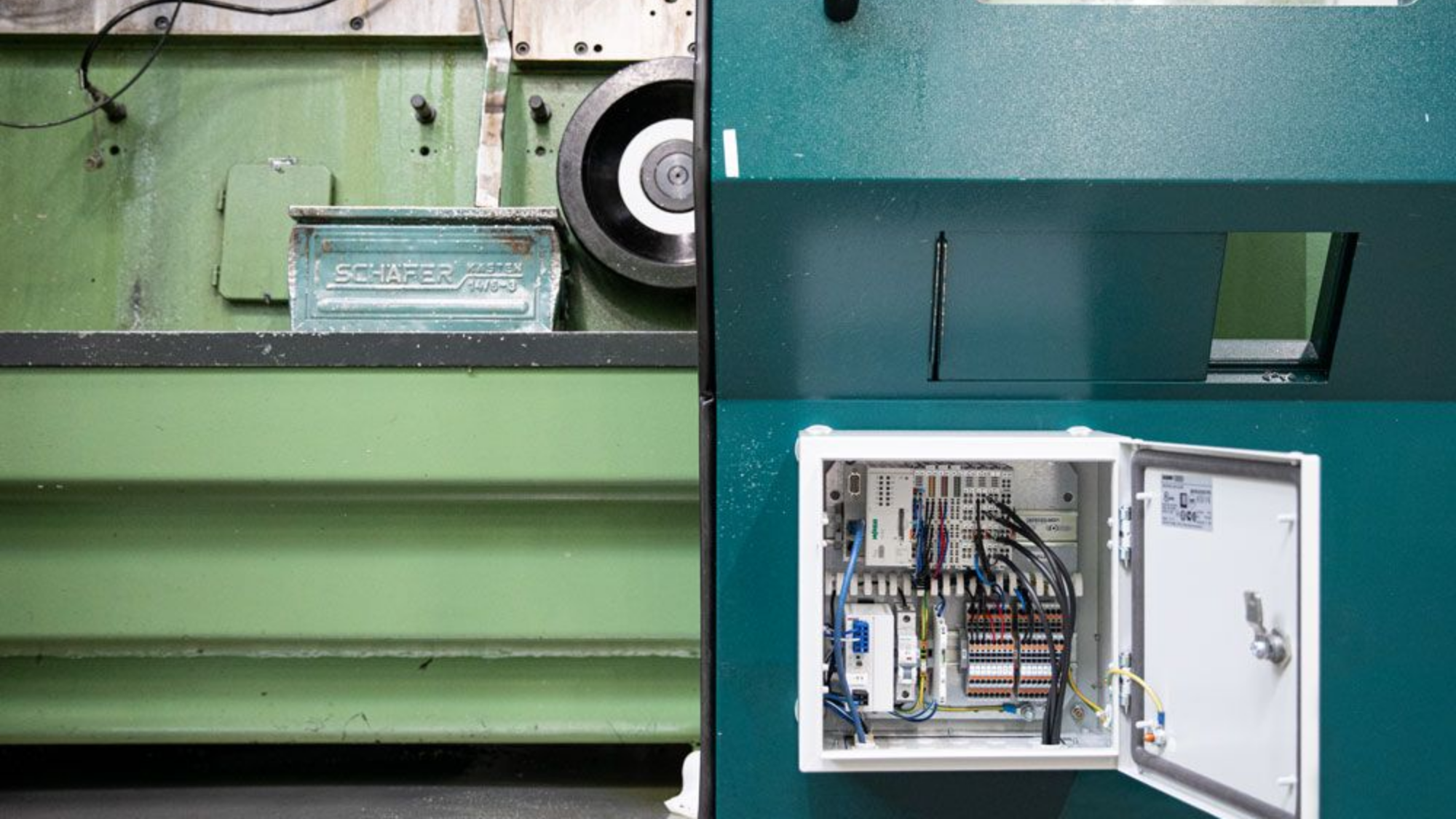

In critical and hazardous process environments, intelligent industrial cameras play a vital role in monitoring and control, significantly enhancing safety. Potential hazards are detected in real time, assessed instantly and necessary responses are automatically triggered.

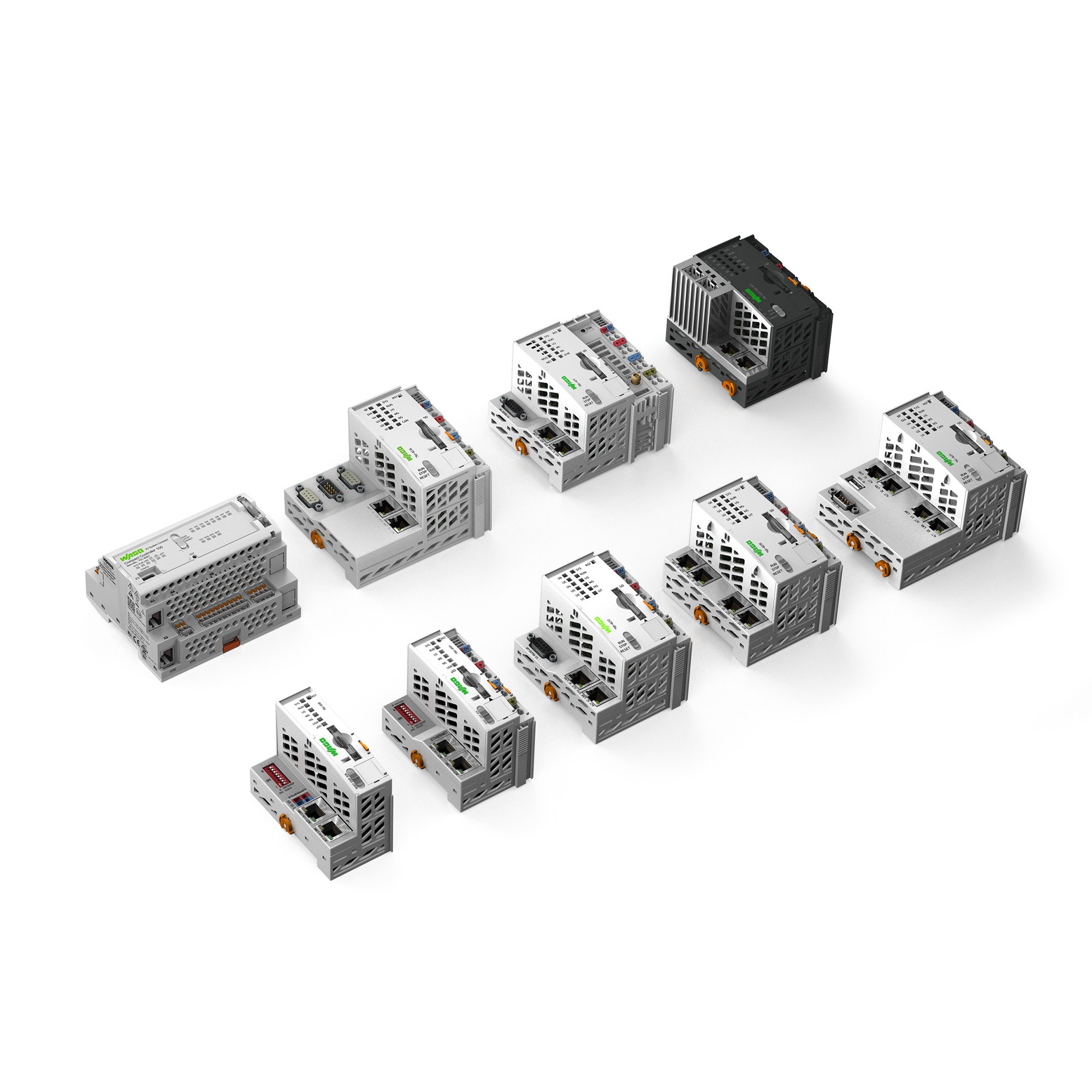

At the core of this solution is a centralized, intelligent OT/IT system that serves as a gateway, ensuring seamless communication between components. Input modules detect signals, while output modules initiate actions, such as activating warning alerts. A unified control system manages camera operations, nd additional monitoring applications – such as thermal reactor monitoring – are also feasible.

Want to learn more? Download the full story for free!