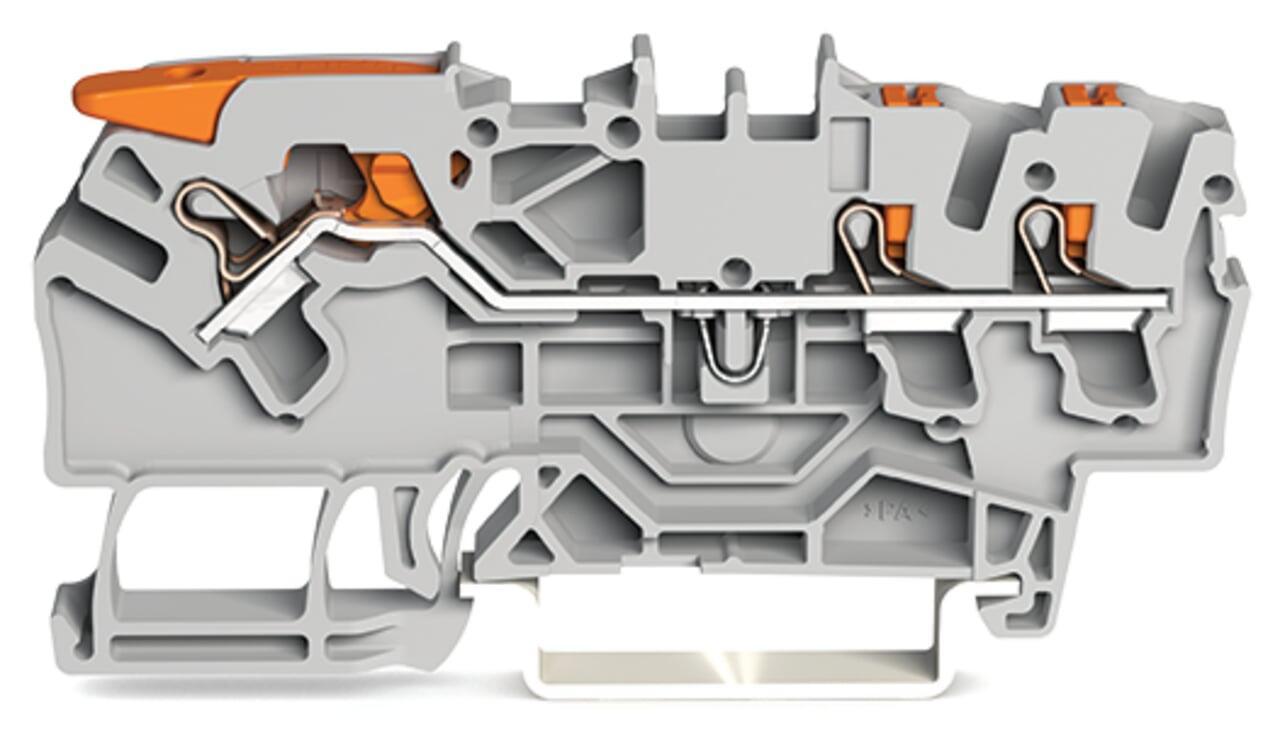

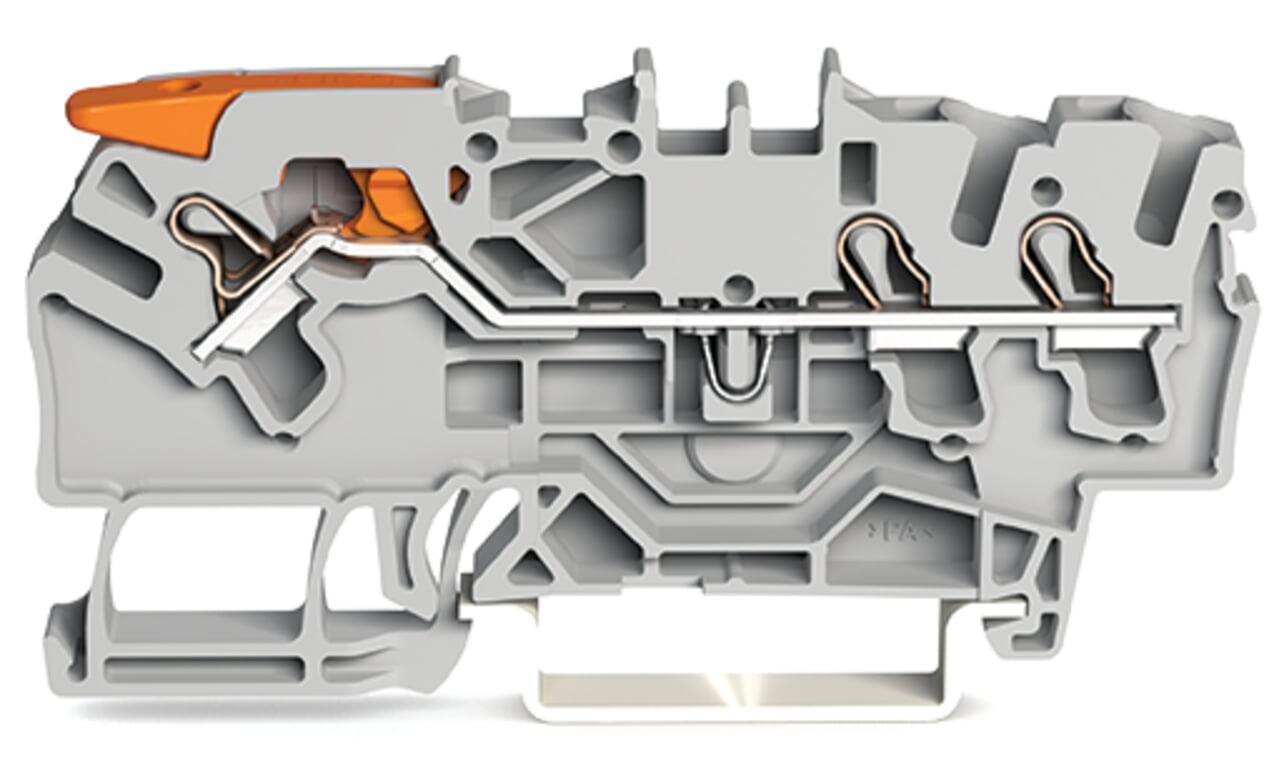

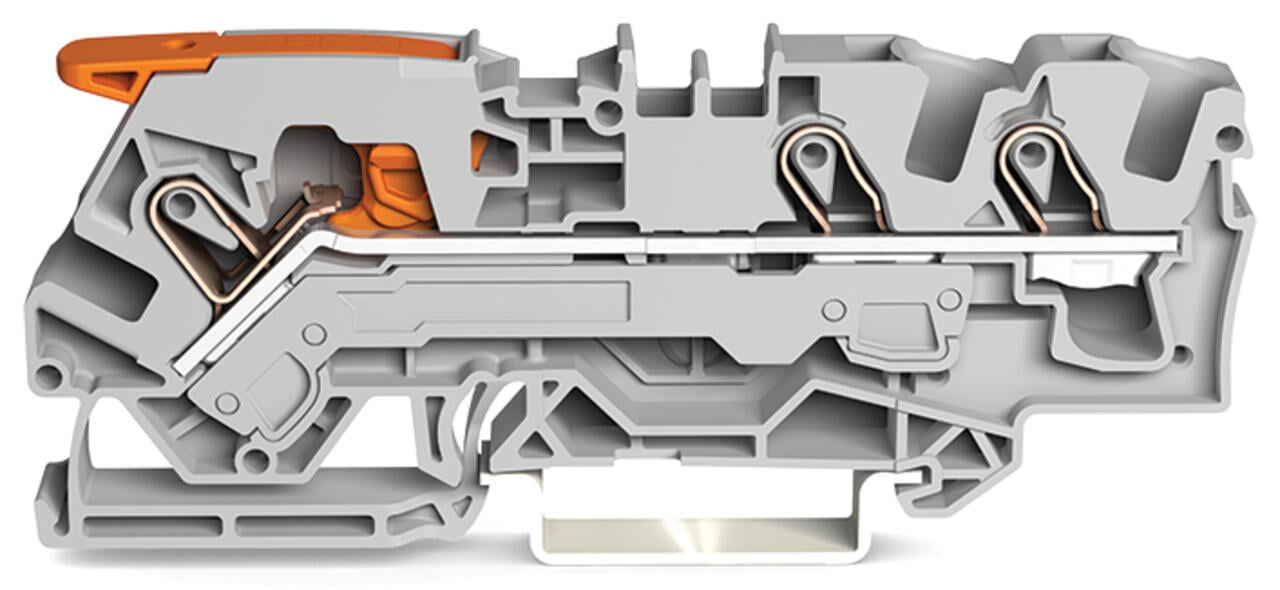

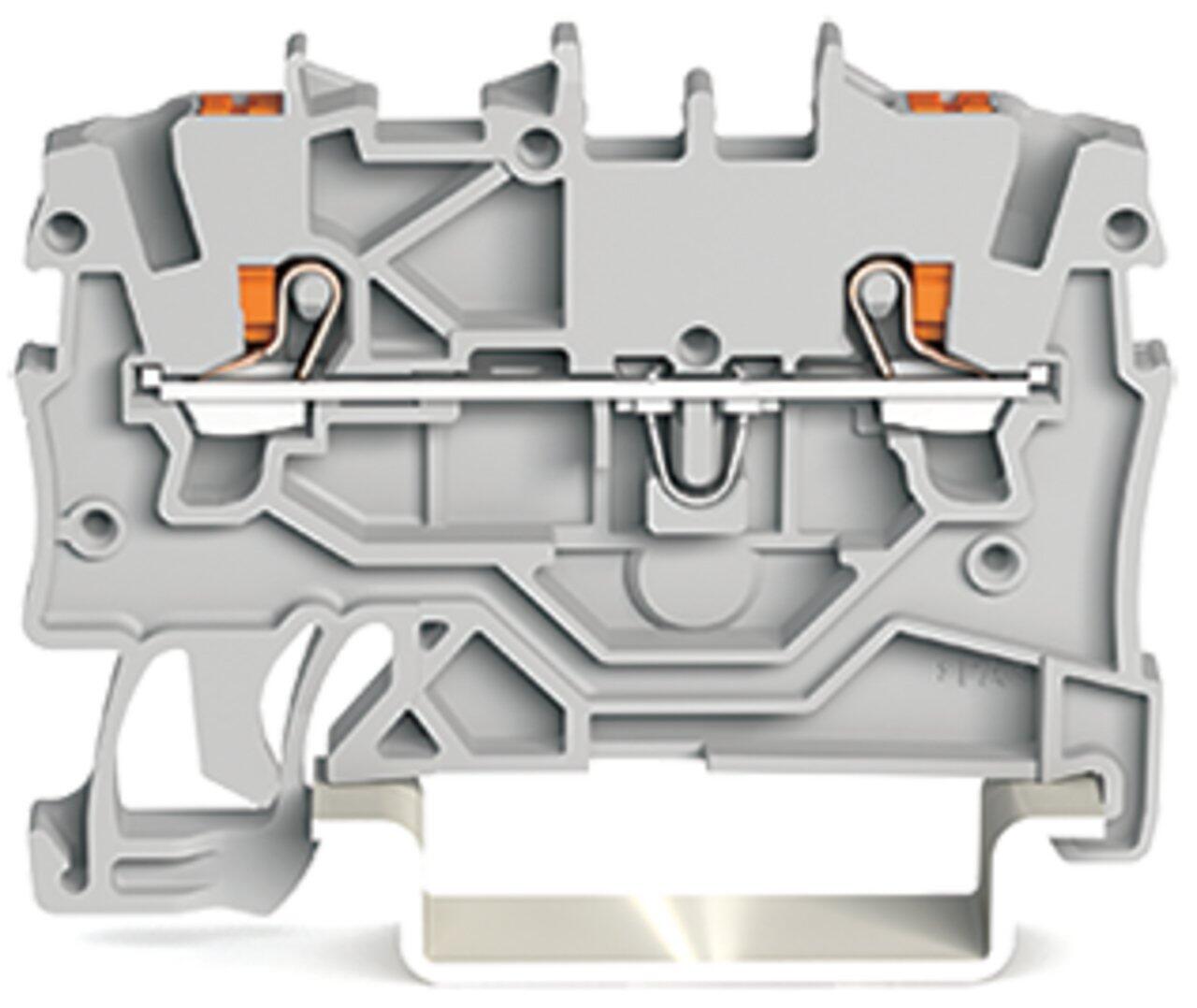

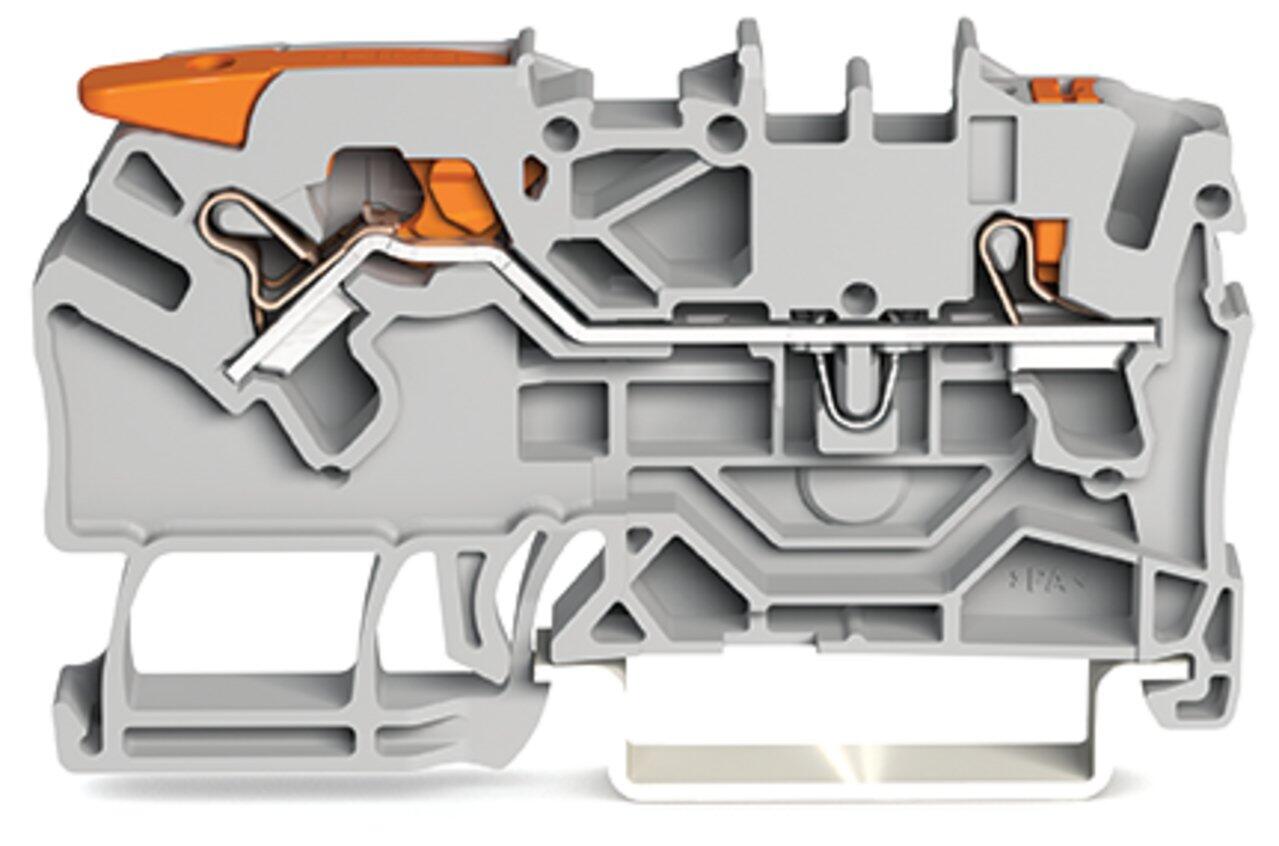

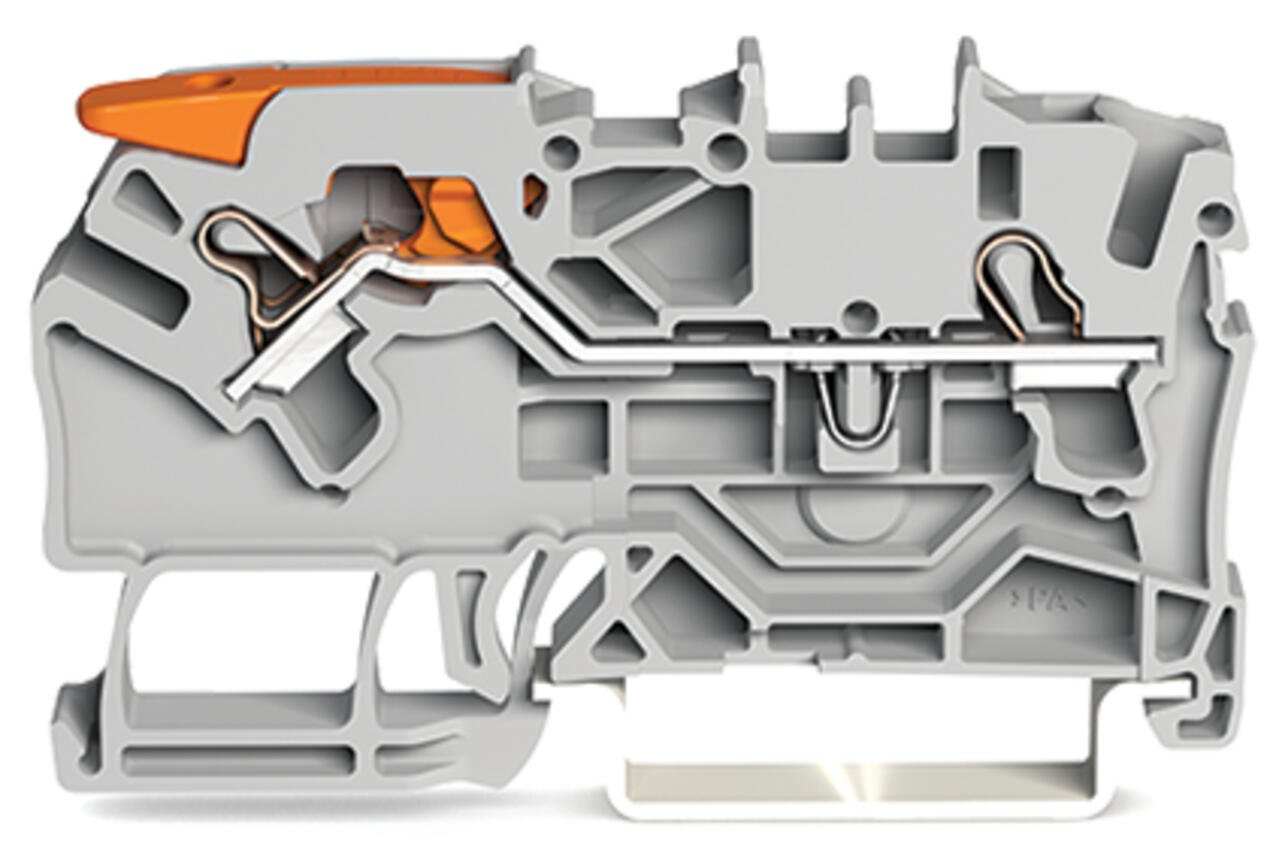

Horlemann and Doris Nienhaus were already able to test their collaboration out some time ago, and the result was a success. “I had a good feeling that Horlemann could help us meet this difficult challenge,” says Nienhaus. Michael Paeßens, from the Power Engineering department of Omexom Uedem, also had the opportunity to work with Doris Nienhaus in previous projects. In Nordvelen, Paeßens is responsible for establishing the power supply at NDM. And where did WAGO come into this? “We’ve collaborated successfully with WAGO for a long time. The new TOPJOB® S Rail-Mont Terminal Blocks with levers offer the customer a very quick and easy connection option,” says Paeßens. It was necessary to establish a temporary connection to supply the pre-heating unit and other parts of the system that are attached temporarily. “With the new rail-mount terminal block, tools are no longer needed. Although the connections are temporary and need to be reconnected again and again, no wear occurs, unlike with screw-clamp connections,” explains Paeßens. This in turn ensures a long service life for the terminal blocks. Another advantage is the marking of the new rail-mount terminal block, which allows plain text marking. This helps the end user immediate grasp where the terminal block is supposed to be used. There are no connection problems anymore. “The newTOPJOB® S Rail-Mount Terminal Block with lever saves us from having to provide long explanations. It’s easy and intuitive to use, in any position, without tools,” concludes Paeßens. Viktor Kamperdick-Voss can confirm that: He is a project manager for power engineering at Omexom Uedem and responsible for developing a connection and electrical feed-in concept. Together with Westnetz GmbH and NDM Naturwerkstoffe GmbH, he created an option for feeding the electric power to the grid. For Kamperdick-Voss, it is especially important to meet customers’ need for providing temporary connections: “With the new TOPJOB® S Rail-Mount Terminal Block with lever, even staff without much training can carry out installation tasks without tools – spontaneously and without needing a second pair of hands to help.”