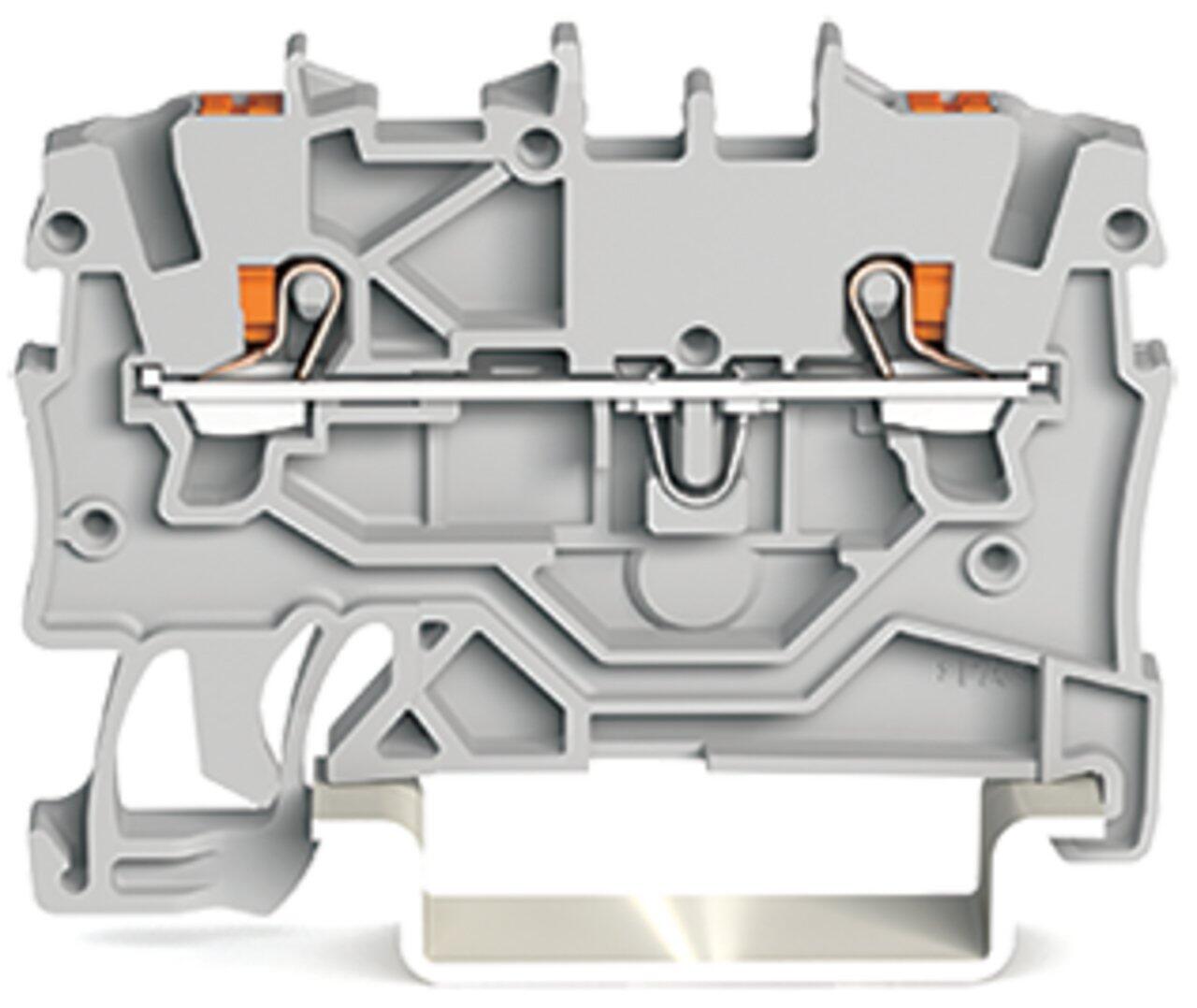

Control Cabinet Manufacturing at Ford Using WAGO Terminal Blocks

Henry Ford was, without a doubt, one of the most important pioneers in automobile production and left his mark on the industry like no one else, through the introduction of assembly line production. The aspiration to always improve processes remains in the company’s DNA up to this day. During a recent factory-wide vacation, the press line at the production facility in Cologne, where chassis parts for the Ford Fiesta are fabricated, was rebuilt and optimized. And a seemingly small element played a major role in this process: a WAGO rail-mount terminal block.

The Ford plant in Cologne has lots of big equipment, but sometimes it’s the little details that matter.

Around 18,600 employees work for Ford in Cologne, where they produce one of their most successful compact car models: Up to 1,400 of the popular compact Ford Fiesta roll off the assembly line daily – and have since 1976! The large punching machines and presses used to produce the chassis components have a lifespan of several decades. However, many of the components and systems involved in the press line don’t last anywhere near that long. For example, during conversion and retrofitting – typically performed during factory-wide vacations – new assemblies are installed, the safety technology is expanded and the electronics are updated. During the process, the control cabinets, including the control and automation technology, as well as the energy distribution, are updated and further optimized.