Safe Pressure Regulation

When smart grids are discussed, the focus is usually on the electrical sector, as is the case for the entire public discourse about the energy transition in general. In contrast, the gas and district heating sectors live in the shadows, at least as far as public perception is concerned. Yet adding intelligence is no less lucrative here. Recently, energy suppliers like DREWAG NETZ from Saxony have employed smart technology at the regional level in gas distribution systems. The I/O technology from WAGO’s 750 Series is used in an increasing number of gas pressure regulating stations in Dresden.

The Benefits of WAGO for You:

Ex i modules within the modular I/O-SYSTEM 750 have been designed specifically for hazardous areas.

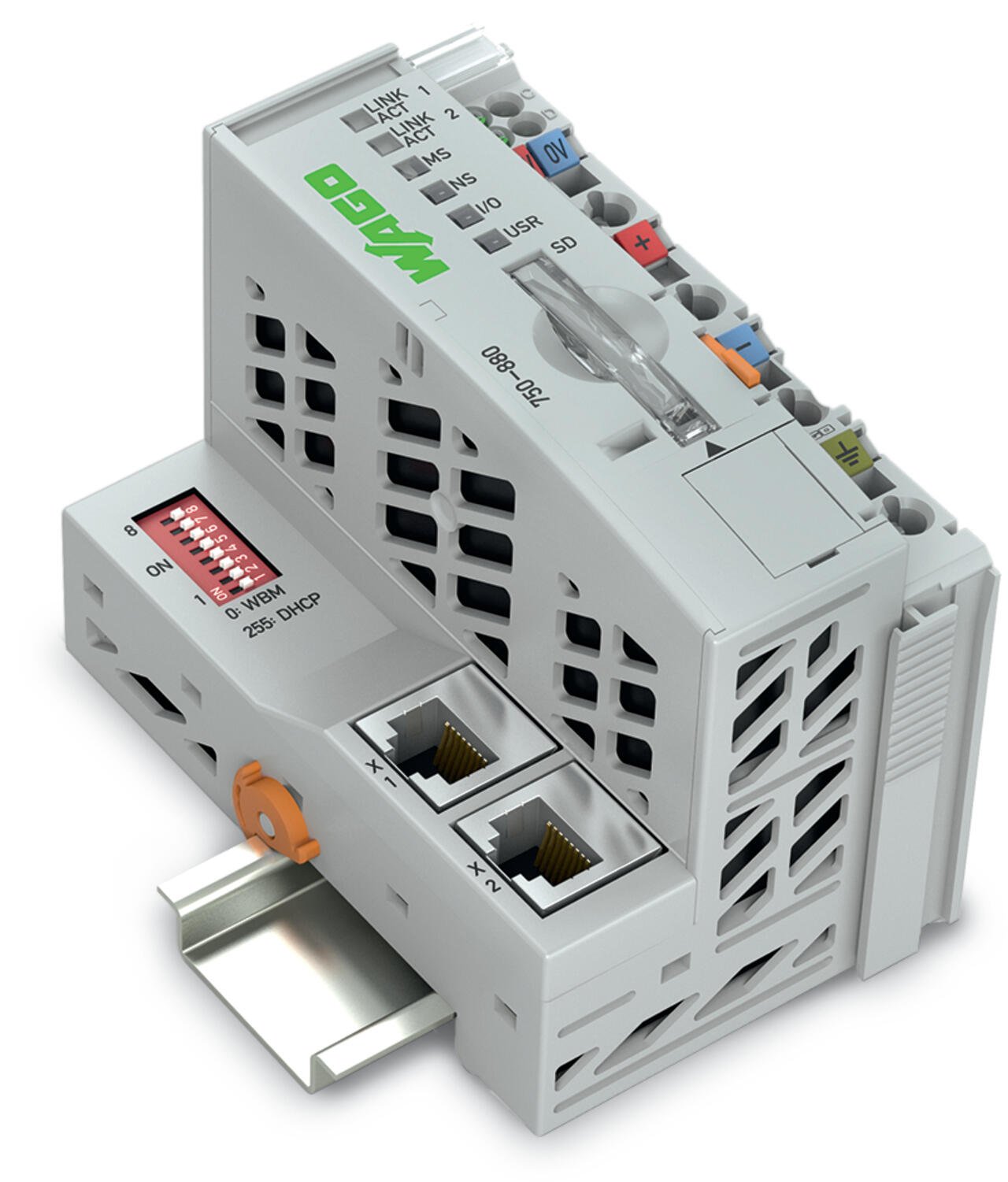

880 ETHERNET telecontrollers support diverse ETHERNET protocols, such as IEC 60870, IEC 61850 and MODBUS (TCP, UDP, RTU)

Reliable, Simple and Economical