Next Generation 4- and 8-Channel ECBs

WAGO’s Next Generation Multi-Channel ECB offering improves channel density and offers even higher current circuit protection. Each configuration takes up just 32 mm on the DIN Rail. 1 to 10 A circuit protection per channel with the option to bind two channels together where 16 A circuit protection can be achieved.

Advantages:

- High switch-on capacity: > 50,000 µF

- Up to 16 A Current Protection

- Group messaging input and output signals for remote control and monitoring

- Approvals: CE, UL 61010-2-201, UL 2367

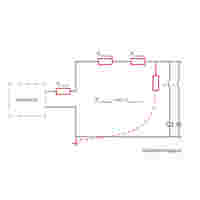

2-, 4- and 8-Channel ECBs

WAGO’s space-saving ECBs come in two, four, or eight-channel protective switches with currents adjustable from 0.5 to 12 A, providing reliable protection with a superior price/performance ratio. They offer outstanding features and reliable protection against overload and short circuits. With a maximum width of 45 mm (1.772 inches), these ECBs feature high channel density to save space in the control cabinet.

Advantages:

- High switch-on capacity: > 50,000 µF

- Communication capability: remote monitoring and reset

- Optional active current limitation

- Approvals: CE, UL 60950, UL 2367, GL

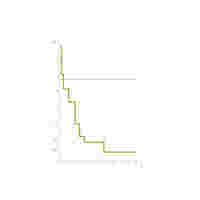

787-3861: Next Generation WAGO Single-Channel Electronic Circuit Breakers

WAGOs next generation 24 VDC, 1-channel ECBs improve operations and offer significant cost savings for customers. New in the 787-3861 family is the ability to configure the S2 output on ALL variants and to report 7 different states including triggered or manually switched off along with early load warnings. These devices no longer have a hard to open cover to access the manual reset wheel, offering an indented button to be operated with a tool. On adjustable units, the current limit can be set via discrete setting wheel instead of a sequence of inputs through the manual input wheel, making it much easier to set and identify current settings.

Advantages:

- Six fixed and two adjustable rated current versions from 0.5 A to 8 A

- LED status indicators to identify device status

- 6mm slimline design

- Easy jumpering to 857 and 2857 series devices with same terminal layout

- High switching capacity: > 50,000 μF for non-NEC Class 2 devices

- S1 Input and Configurable S2 Output for easy remote monitoring and control

- Approvals: CE, UL 61010, UL 2367, and UL 1310 NEC Class 2 Versions

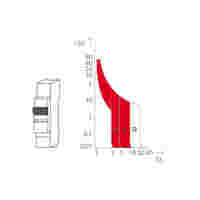

787-2861: Single-Channel Electronic Circuit Breakers

These 24 VDC modules are just 6 mm (0.236 inch) wide, making them the slimmest ECBs currently available. They are approximately 66% smaller than miniature circuit breakers, saving even more space, particularly when used in control cabinets. These ECBs enable high-capacity loads greater than 50,000 µF to be switched on – helping you reduce false tripping due to inrush currents.

Advantages:

- Seven versions available for rated currents of 0.5 A to 8 A

- Color coded according to nominal current

- Wide surrounding air temperature range: −25 … +70°C (−13 … +158°F)

- Powering on/off and resetting directly on the module or remotely via digital input signal

- Triggered signal output can be combined as a group signal for up to 30 devices

- Approvals: CE, UL 61010, UL 2367