Megawatt Solar Parks: WAGO Switches Help Keep Track of Data in the Control Cabinet

Gantner Instruments, a specialist in photovoltaic monitoring and control, uses WAGO switches in the control cabinet for optimal network diagnostics – for more flexibility, a high level of reliability and easier planning.

Solar energy is clean, sustainable and safe. Gigantic photovoltaic power plants are expected to radically change the global energy supply in the coming years. The smooth operation of such PV systems is indispensable for high-yield power generation through solar power – and can only be ensured through consistent, location-independent data monitoring. As a full-range supplier for monitoring, control and analysis of large-scale solar plants, Gantner Instruments is making a contribution to forward-looking development of renewable energies.

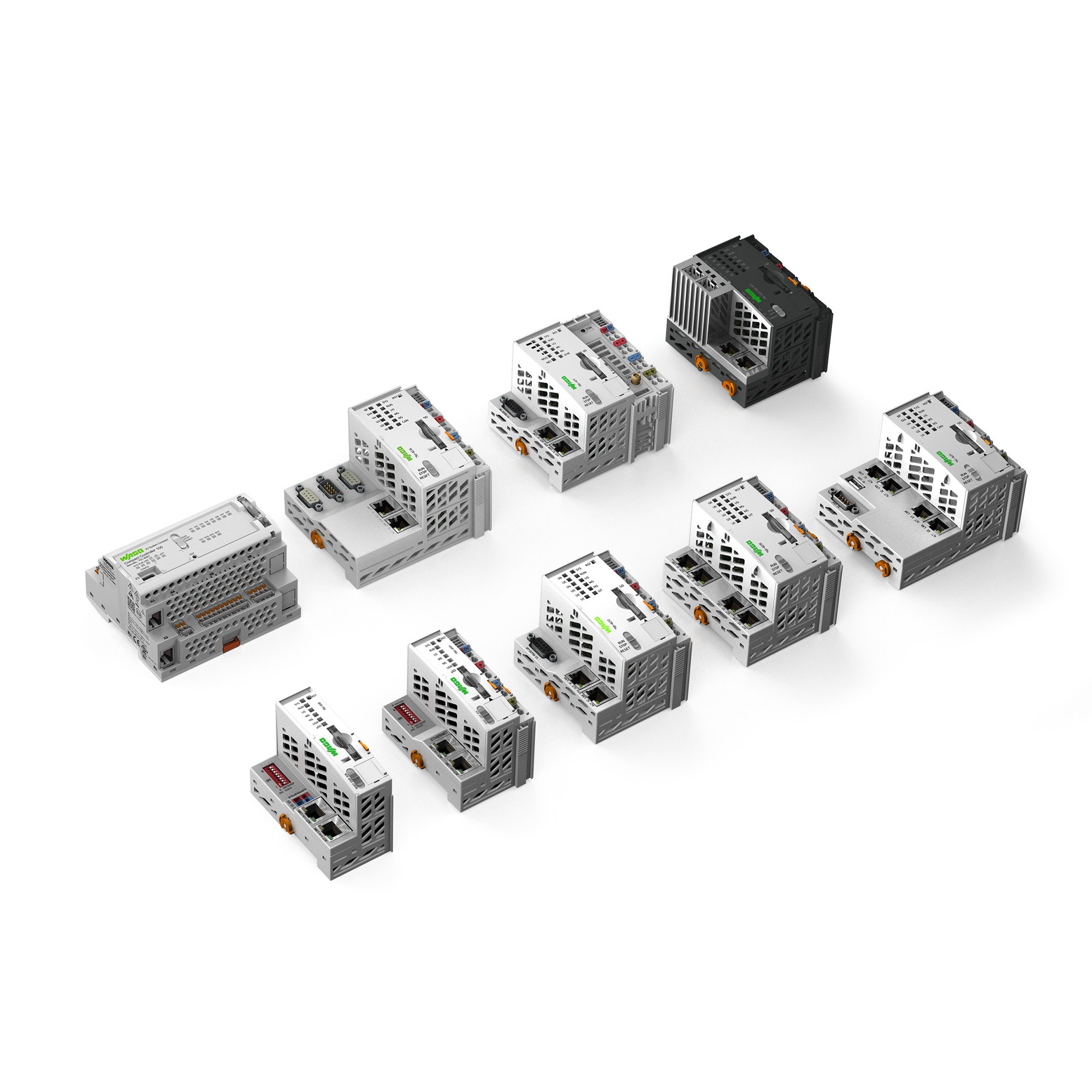

For networking the decentralized control cabinets, the company relies on ETHERNET switches from WAGO. These powerful managed switches are a typical example of how the Minden-based interconnection and automation company helps increase availability and supports the entire lifecycle of a control cabinet with its products: from planning and production, to testing, commissioning and ongoing operation.

Benefits of WAGO Switches:

Planning: temperature simulations before first use

Manufacturing: easy DIN-rail mounting and quick accessibility of product documentation and operating instructions via 2D barcode

Testing: accelerated commissioning and troubleshooting with the help of a diagnostic dashboard

Operation: simple, seamless transfer of all information thanks to integrated Modbus TCP interface