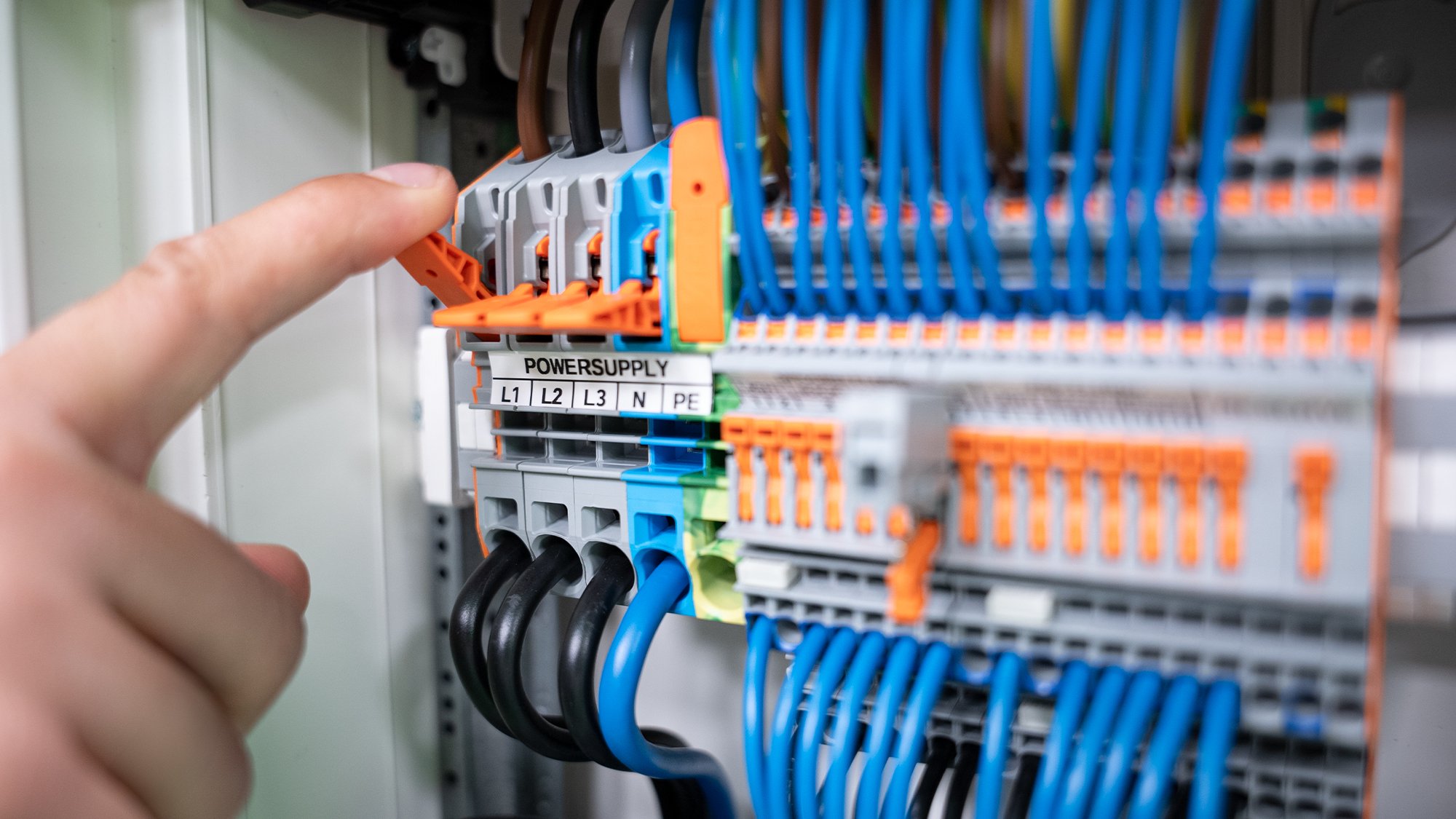

Example 2: Fast power supply with difficult-to-bend, large conductor cross-sections for industrial applications

The supply of high currents requires the connection of large conductor cross sections. High-current terminal blocks with POWER CAGE CLAMP connection technology are the right choice for applications in large building complexes or industry. They provide optimal contact force for conductor cross-sections up to 35, 50, 95 and 185 mm2(2, 2/0, 4/0 AWG and 350 kcmil). This makes high-current terminal blocks the perfect solution for energy-intensive applications, e.g. mechanical and systems engineering, as well as power engineering. And all this using spring pressure connection technology, eliminating time-consuming preparation of large conductor cross-sections with crimping ferrules or cable lugs. What's more, the high-current terminal blocks have lateral conductor entry, and the clamping point can be locked in the open state. This is especially important for large conductor cross-sections that are difficult to bend, because locking in the open position frees up both hands for you to work with.

Nor do users need to worry about tightening torque when connecting conductors: The spring pressure presses the conductor onto the current bar via two clamping brackets, ensuring excellent conductor contact – regardless of the operator’s level of care.