Looking to the Future

WAGO products are used globally in factories, ships, rail and electrical networks, from the desert to the tundra. Sometimes, they endure a lot: dust, dirt and shocks, as well as scorching sun, icy winds and the muggy tropics. Protection against the harsh environment comes from tailor-made housings, which WAGO – like many other plastic components – often manufactures itself.

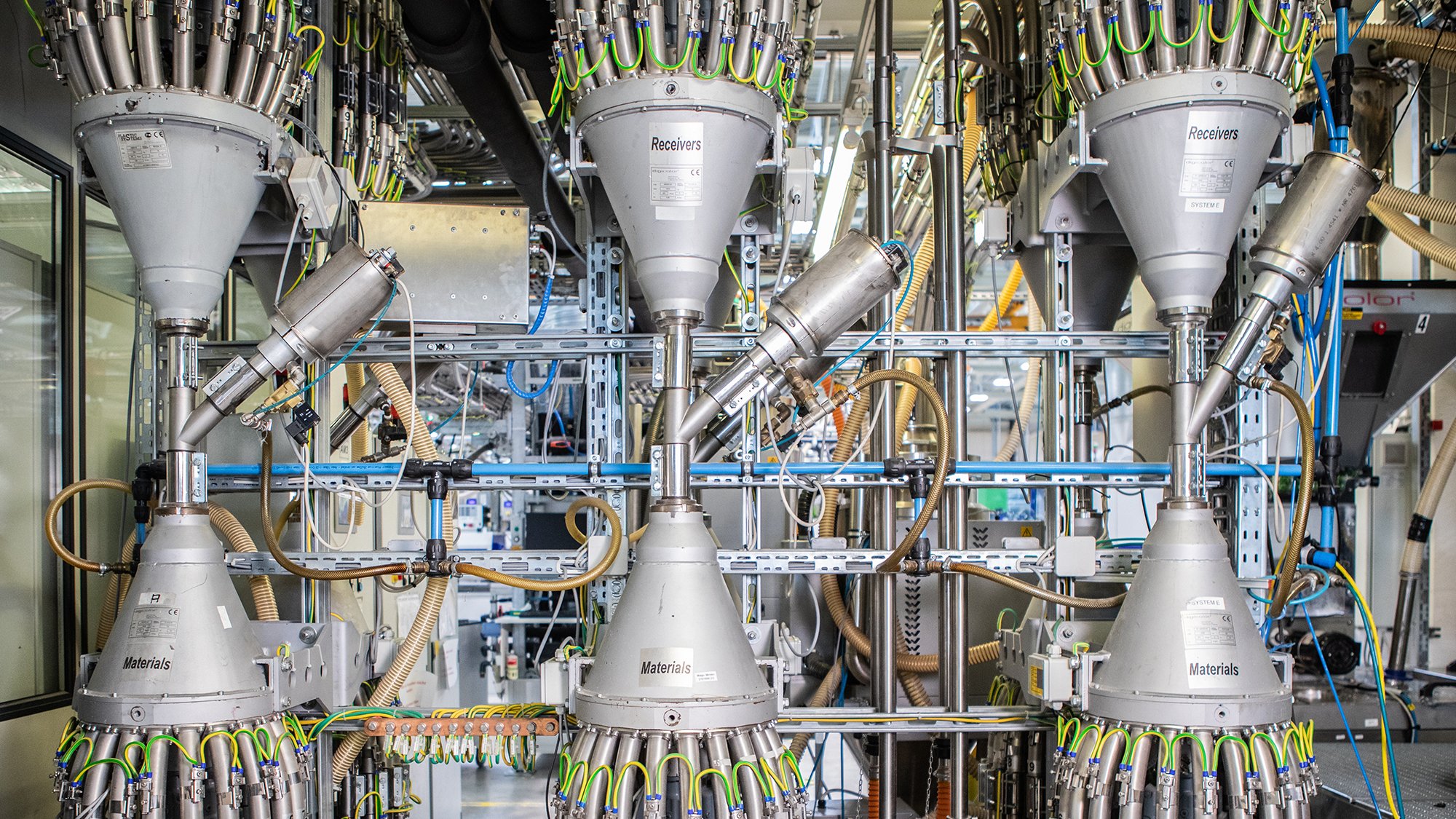

Various plastic granules are the base material for the housings; these granules are transported to the injection molding machines by a tube system. This occurs via vacuum pumps, which produce a vacuum. Like the good old pneumatic tubes, the pumps transport the different granulates to where they are needed immediately. However, the airflow inevitably also carries some dust. To prevent this from damaging the pumps, filters are installed in the exhaust air pipes.