Single and Three Phase Inputs with 24 VDC Output

Single and Three Phase Inputs with 12 VDC or 48 VDC Output

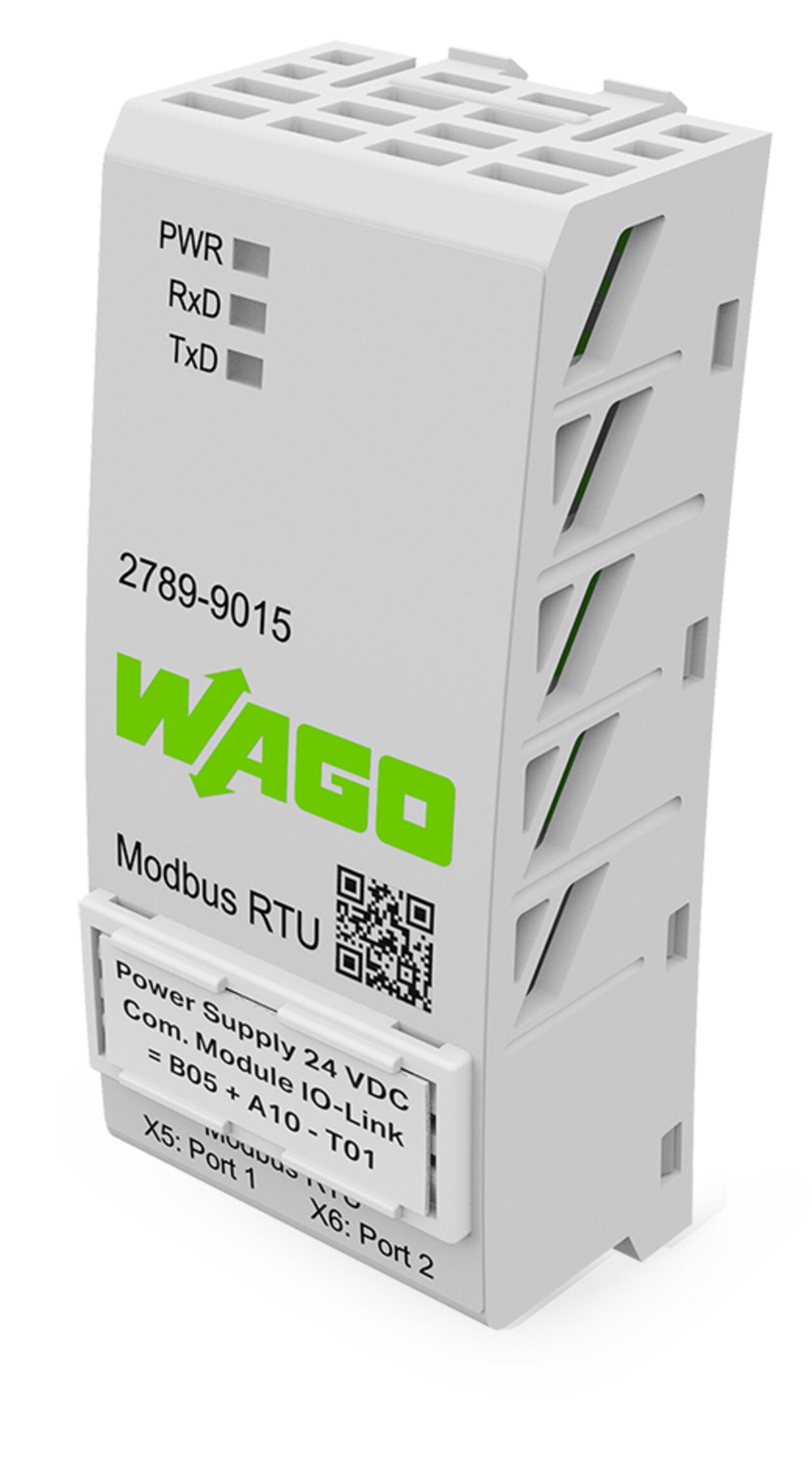

Communication Modules

New Products

A Wide Range of Applications Thanks to New 12 V/ 24 V /48 V Models

Extended Product Range for the Manufacturing Industry

The WAGO Pro 2 Power Supply portfolio is expanding with the addition of 12 V, 24 V and 48 V models. These new devices support a wide variety of applications, such as supplying power to stepper motors, other DC drive technology, powerful contactors and other components.

Reliability, Cost Savings and Safety

The expansion makes the Pro 2 Power Supply’s familiar features, such as reliability, cost savings and safety (thanks to integrated communication for monitoring and parameterization), available for 12 VDC, 24 VDC and 48 VDC devices. Using a power supply unit to monitor the power supplied to the drive technology can significantly increase the fail-safety of a specific application. The power reserves of the subordinate power supplies are also ideal for start-up and sudden load changes.

Power Supply 4.0 – More Power for Your Control Cabinet

WAGO’s line of Pro 2 Power Supplies, with units ranging from 120 to 960 W, sets new standards for communication and parameterization flexibility. It also offers energy conversion efficiency of up to 96.3 %. These new power supplies permit fieldbus connection via snap-on type communication modules and feature high-performance TopBoost and PowerBoost capabilities for to reliably ensure system availability.

The Benefits for You:

- The power reserves of the subordinate power supplies are ideal for start-up and sudden load changes.

- Provides reliable, fail-safe operation and lowers costs by preventing unplanned downtime

- All the familiar features of WAGO’s Pro 2 Power Supply are available

Reliable Protection for a Long Service Life

A coating protects Pro 2 Power Supplies.

Dust, moisture and aggressive vapors that frequently occur in many applications can severely affect electrical and electronic devices. But how can mission-critical electronics be protected against these typical environmental hazards to ensure day-to-day reliability and protect your investment? Protective coating, when used on components and PCBs, has proven effective. This finding has led WAGO to now offer a Pro 2 Power Supply model with this protective coating. Compliant with EN 60068-2-60, based on ISA 71-04, G3 Group A, the coating protects against oxidation caused by corrosive gases (e.g., NO2, SO2, Cl2, H2S) and salt spray, as well as moderate humidity. With the protective coating, these power supplies carry UL HazLoc Class I Div 2 Group A, B, C and D certifications, verifying their suitability for hazardous areas. When equipped with this durable coating, WAGO’s Pro 2 Power Supply is ready for process engineering, supply and disposal companies and operation in harsh industrial environments.

The Benefits for You:

- Protection against corrosive elements such as oxidation due to corrosive gases, salt spray and humidity

- Increased device durability, even in harsh environments

- Provides reliable, fail-safe operation and lowers costs by preventing unplanned downtime

- All the familiar features of WAGO’s Pro 2 Power Supply are available

With DNV-GL Approval and HazLoc

WAGO’s Pro 2 portfolio expands for marine environments and hazardous areas.

Shipboard and coastal applications are challenging. Mechanical stress, such as vibration and shock, compounded by environmental factors, such as humidity, heat or salt spray, can severely degrade electrical and electronic devices. WAGO’s Pro 2 Power Supplies meet these challenges with an DNVGL-approved version that is now available and offers optional protective coating.

Use in Marine Environments

Marine certification ensures that the power supplies not only can stand up to harsh environmental influences, but also have both lower emission of interference and higher EMC. Furthermore, the power supplies also provide reliable operation at vibrations of up to 0.7g. The available version with a coated PCB also increases resistance to salt spray corrosion.

Process Industry Applications

Additionally, UL HazLoc approval, which is the US certification for hazardous locations per UL Class 1, Div. 2, Group A, B, C and D, expands the WAGO Pro 2 Power Supply’s range of applications. The optional protective coating also increases corrosion resistance to harmful gases and is tested in compliance with the ISA G3 standard. Typical applications for these power supplies are: Ships and marine equipment and onshore/offshore applications (e.g., wind turbines) in environments with increased vibration, as well as in machines and equipment (e.g., in process engineering, where explosive air–gas mixtures are expected only rarely and for a short period).

The Benefits for You:

- Reliability thanks to high resistance against environmental influences such as shock, vibration, temperature, humidity, harmful gas, and salt spray

- Safety in hazardous areas, proven by approval per UL HazLoc Class 1, Div 2, Group A, B, C, D

- Very good EMC resistance and low interference emission, proven by compliance with EMC requirements according to DNVGL

Communication

Pluggable communication modules provide continuous fieldbus communication for important data such as output current and voltage. The modular approach is fieldbus independent and provides solutions for most major protocols such as Modbus RTU, IO-Link, Modbus TCP/IP and Ethernet IP.

Configuration

Free interface configuration software offers local and remote parameter setting. Easily tailor your power supply to meet your system requirements.

Challenging Environments

PRO 2 Power Supplies can be used in extreme temperature ranges from -40° C ... + 70° C with minimal derating starting at +60° C.

Load Management

PowerBoost allows for easy switching of capacitive loads and high start-up currents thanks to 150% output power for 5 seconds. TopBoost allows for reliable tripping of circuit breakers by providing 600% power reserves for 15 ms.

Design

Save cabinet space with a slim design and less spacing required between devices. 2D/3D data is available in all relevant formats. The pluggable connectors are laveled in accordance with EN 81346-2 to eliminate wiring errors.

Efficiency

Reduce losses, save cabinet sace and increase energy savings thanks to 96% eficiency.

Reliability

An MTBF > 1,000,000 hours and long service lives of the components mean lower costs compared to other manufacturers.

Installation

CAGE CLAMP spring pressure connection technology provides fast, vibration-proof and maintenance-free termination of solid, fine-stranded or ferruled conductors. Pluggable connectors offer pre-assembled wiring and ease of installation.

Technical Support-Interface