Efficiency in District Heating Control Center

The municipal utility supplies the primary circuit of the district heating network with at a supply temperature of 110 °C of – it is able to tap into the thermal energy produced by the power-heat coupling in the city’s power plant for heating and hot water. There is broad acceptance of district heating in Flensburg and the surrounding areas. Frank Nicolaisen, Team Leader in telecontrol transmission technology at the municipal utility, cites as proof the impressive connection participation rate of 98 %. “District heating is politically popular and is thus easy to support in Flensburg.” The municipal utility currently supplies 60,000 customers in Flensburg, Harrislee, Glücksburg, Tastrup, Wees and the Danish border city of Padborg.

The Benefits of WAGO for You:

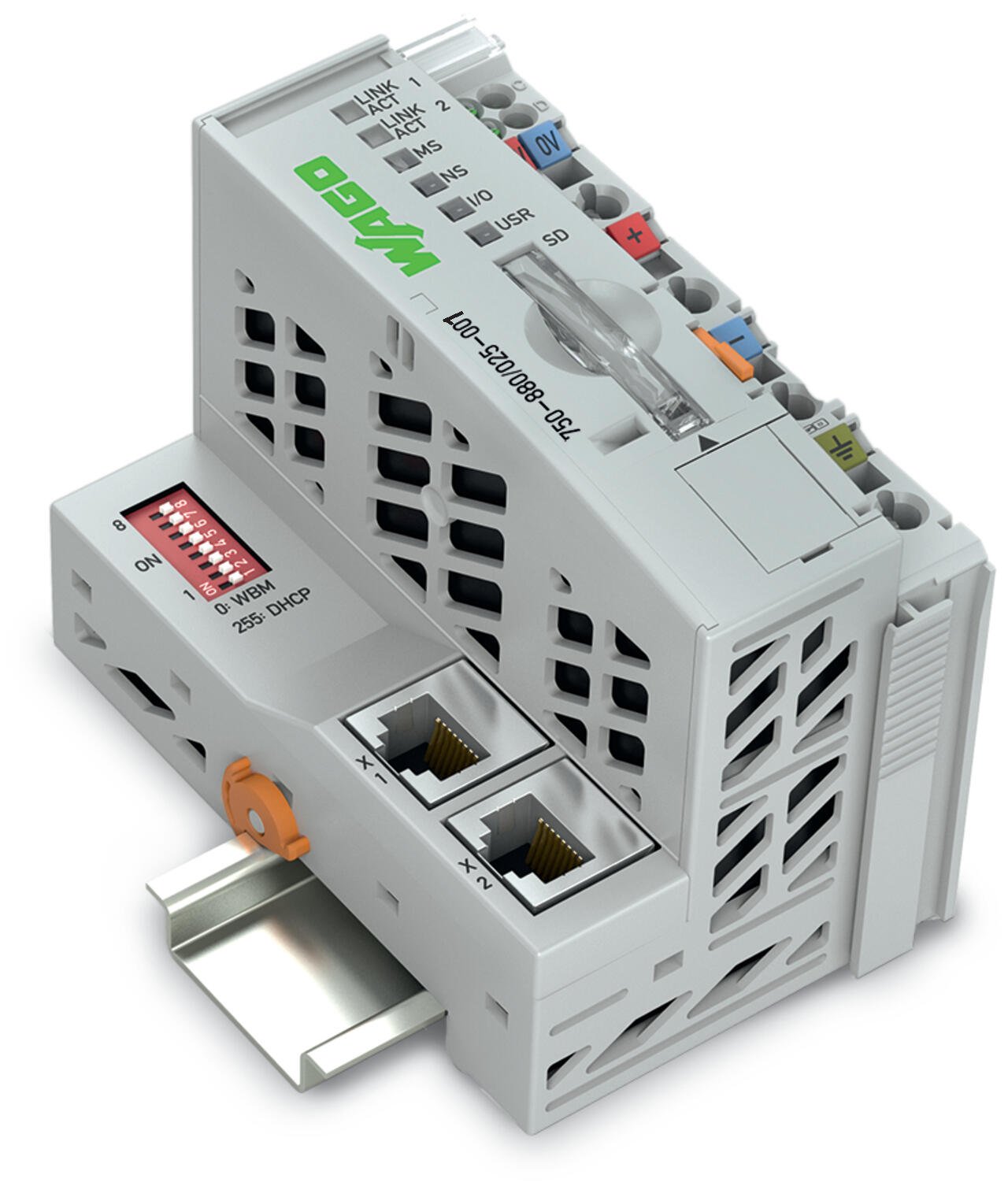

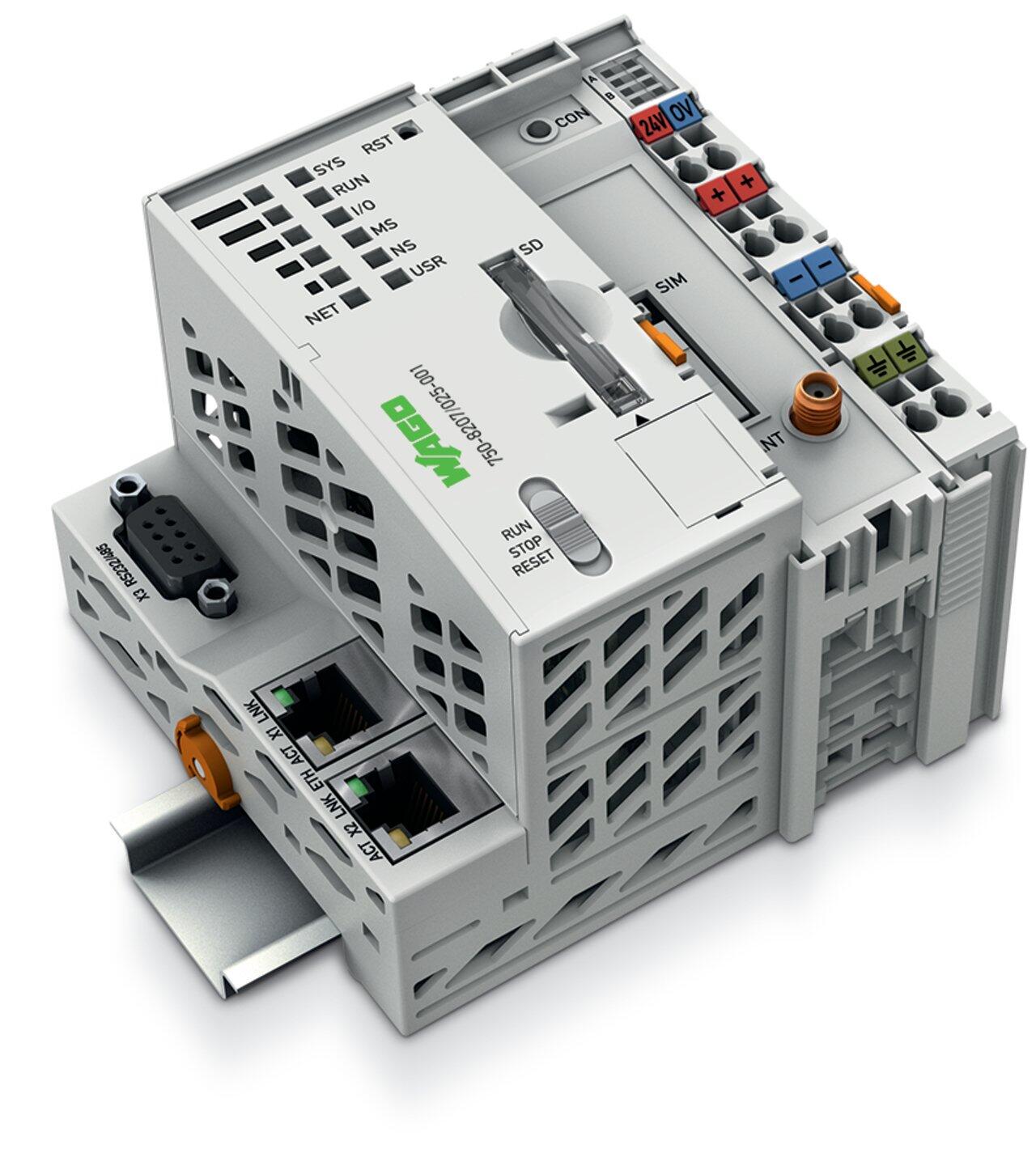

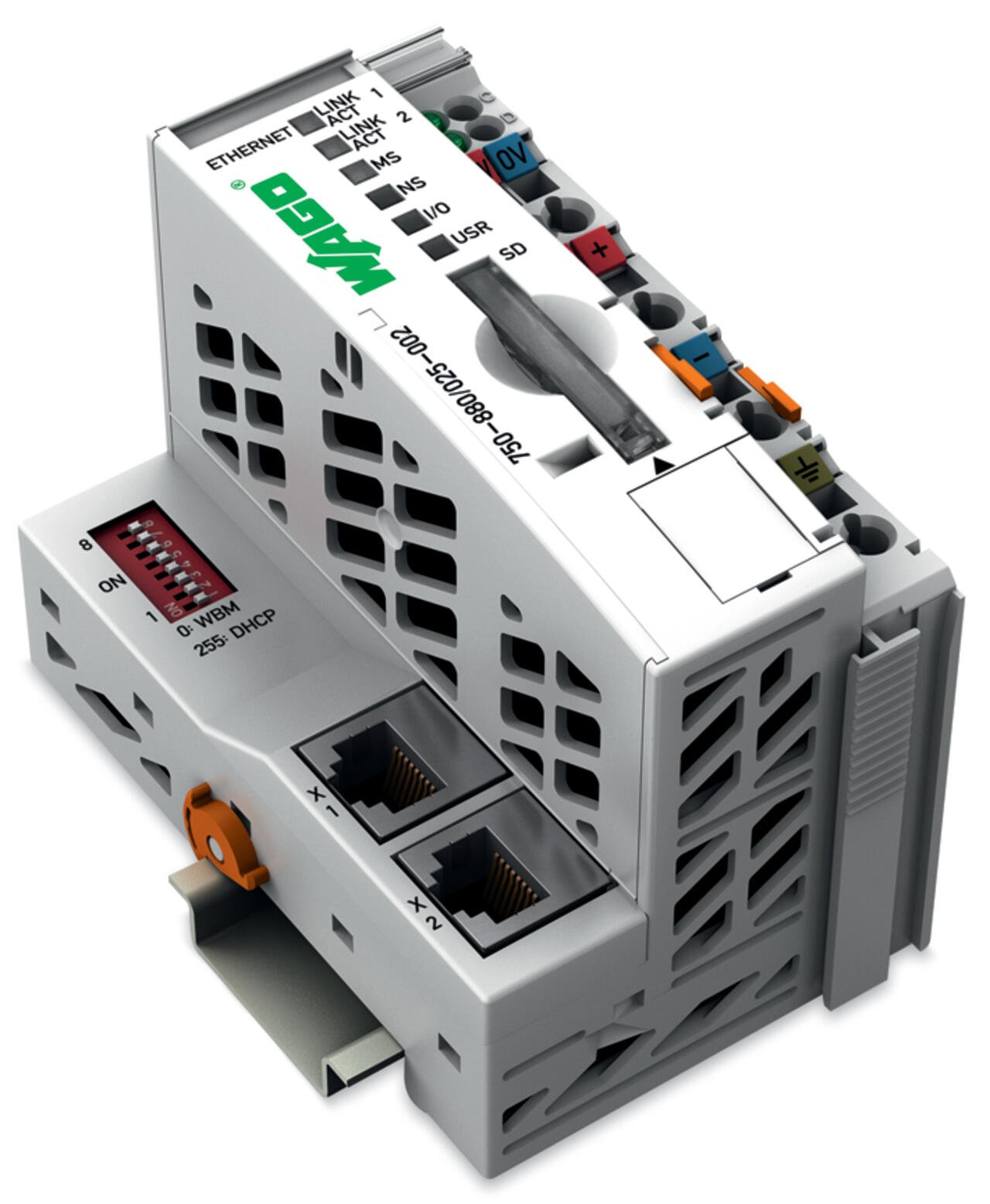

Decentralized control and connection to the remote monitoring

TCP/IP communication per IEC 60870-5-104

Efficient need-based control