Automated Loading Documentation

The Best of Three Worlds – United for a Common Goal

In This Article, You Will Learn:

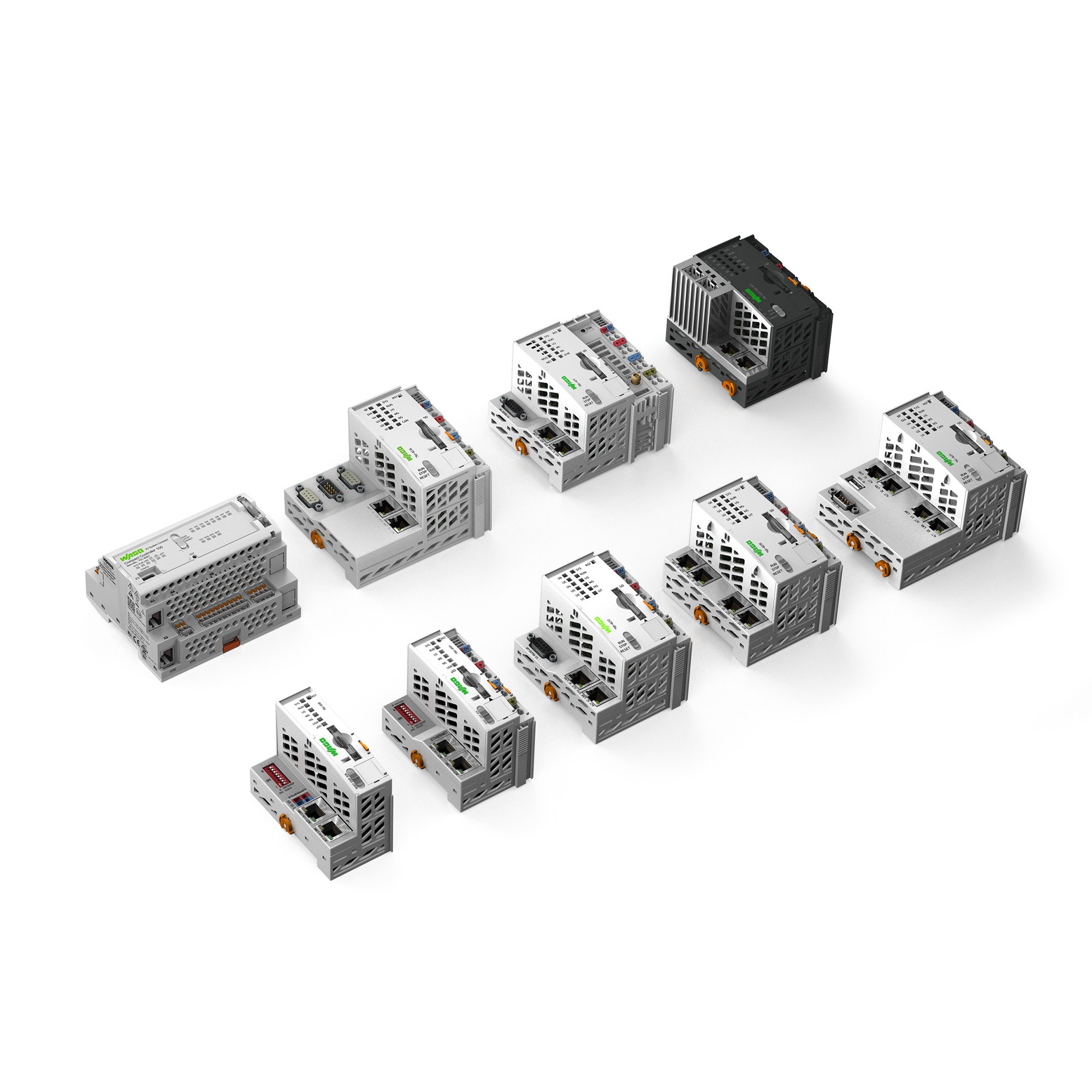

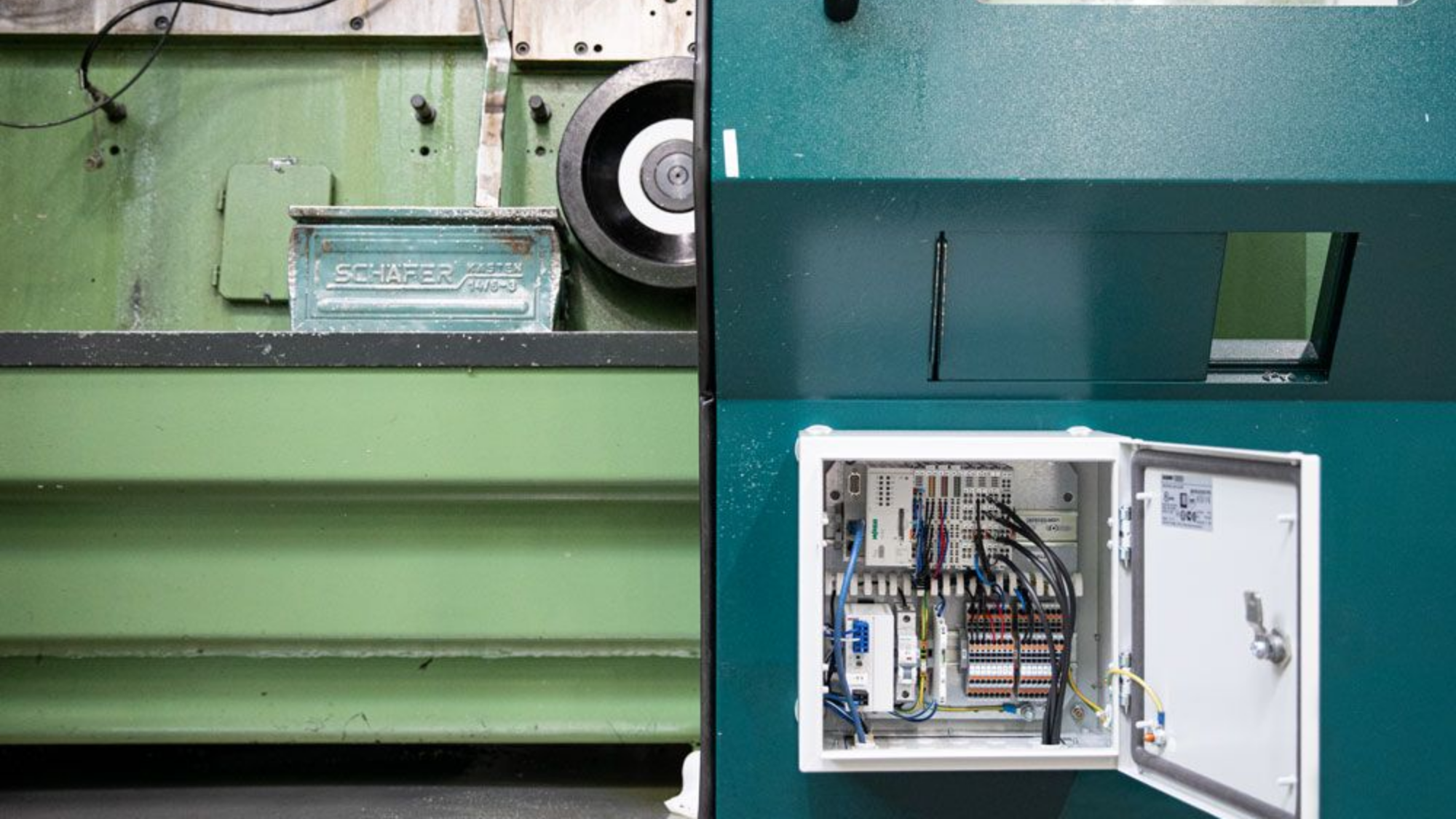

The role of intelligent industrial cameras and the WAGO IoT Box in loading documentation.

The possibilities for automating the control and loading process of containers.

How the WAGO controller facilitates data protection-compliant documentation.