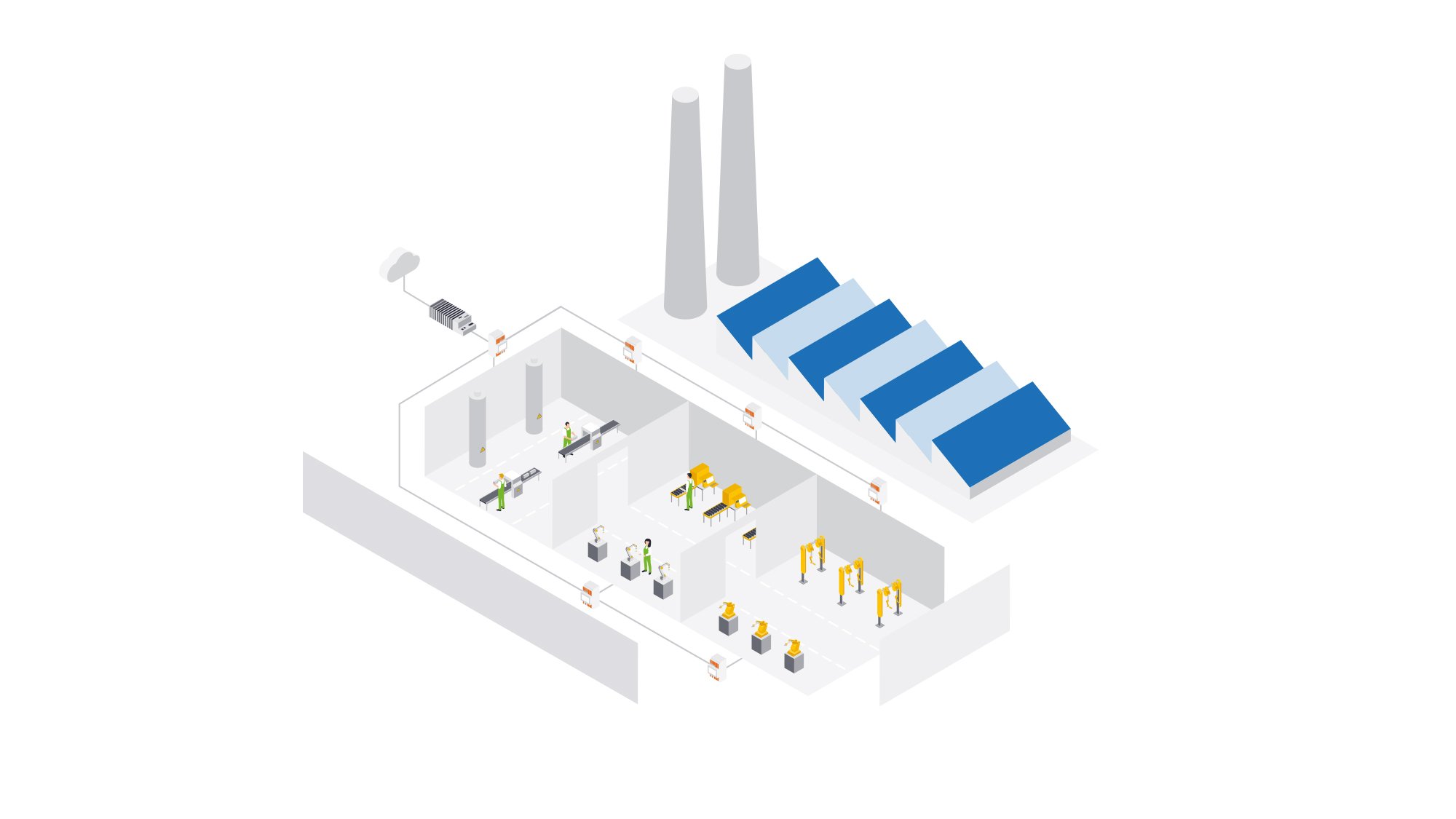

Decentralized Infrastructure Automation

Companies are focusing on decentralized infrastructure automation more and more. When monitoring system systems – whether distributed production facilities, power grids, transport systems or energy systems – remote signals can be recorded in a wide variety of applications and integrated into an IT infrastructure. One example: recording data in waterworks.

Recording Data in Waterworks

The data is often widely distributed, and certain areas lack reception. Highly qualified employees often spend hours driving just to read out simple measured values, such as levels and volume flows, and record them in government-mandated reports. In a joint project with Endress + Hauser and the Oberzent water supply system, LoRaWAN has provided the communication, thus allowing automated data collection. With the flexible gateway of the WAGO IoT Box, recorded signals can be passed on to an IT infrastructure.