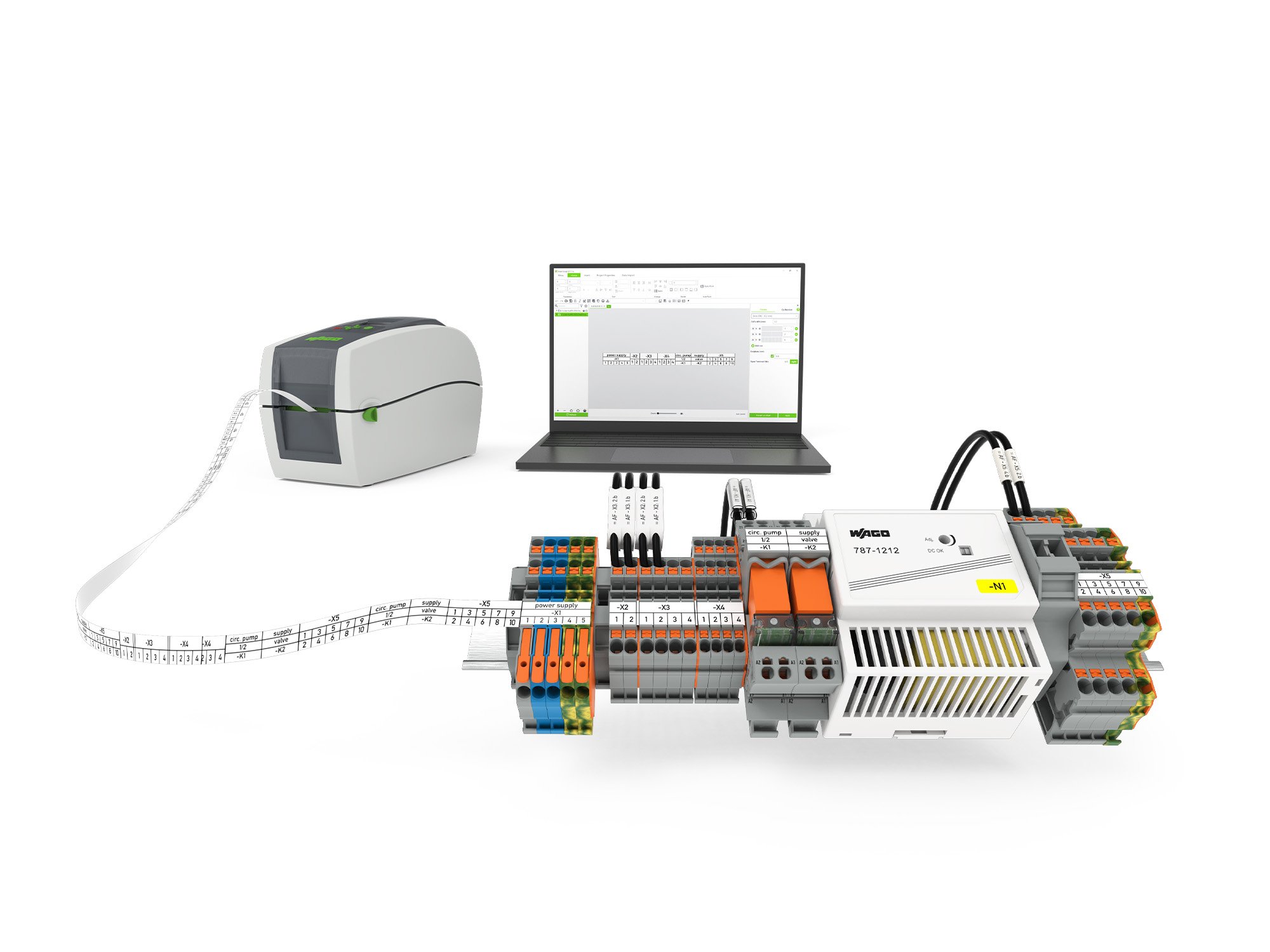

Marking for a Streamlined Control Cabinet Overview

With perfectly coordinated hardware and software, WAGO offers you powerful tailored solutions to save more time and prevent errors in control cabinet marking:

- Direct printing of markings from the EPLAN, WSCAD and ZUKEN CAE systems through the interface to WAGO’s Smart Script marking software; optional data transfer from other CAE systems via data import

- Print durable, order-specific, smudge- and scratch-resistant markings with WAGO’s thermal transfer Smart Printer.

- Complete control cabinet marking with WAGO: Multiline printable marking strips in particular in particular provide clearer organization in the control cabinet.